OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

2026 Top Powder Coating Booth for Sale Options to Consider?

When searching for the best powder coating booth for sale, various factors come into play. Experts like John Smith emphasize the importance of quality and efficiency. He once said, “Investing in the right booth makes all the difference in finishing quality.” This statement rings true in a market filled with options.

The decisions can be overwhelming. Buyers often focus solely on price, overlooking essential features. For instance, airflow and filtration systems directly impact the final product. An inferior booth might save money but could lead to increased costs over time. Moreover, considering future needs is crucial. A booth suitable today may not meet the demands of tomorrow.

Choosing a powder coating booth for sale requires thoughtful reflection. It's easy to get caught up in the sales pitch and glossy advertisements. However, a thorough evaluation of your specific needs is vital. Remember, the right choice must balance budget constraints and quality expectations.

Types of Powder Coating Booths Available in 2026

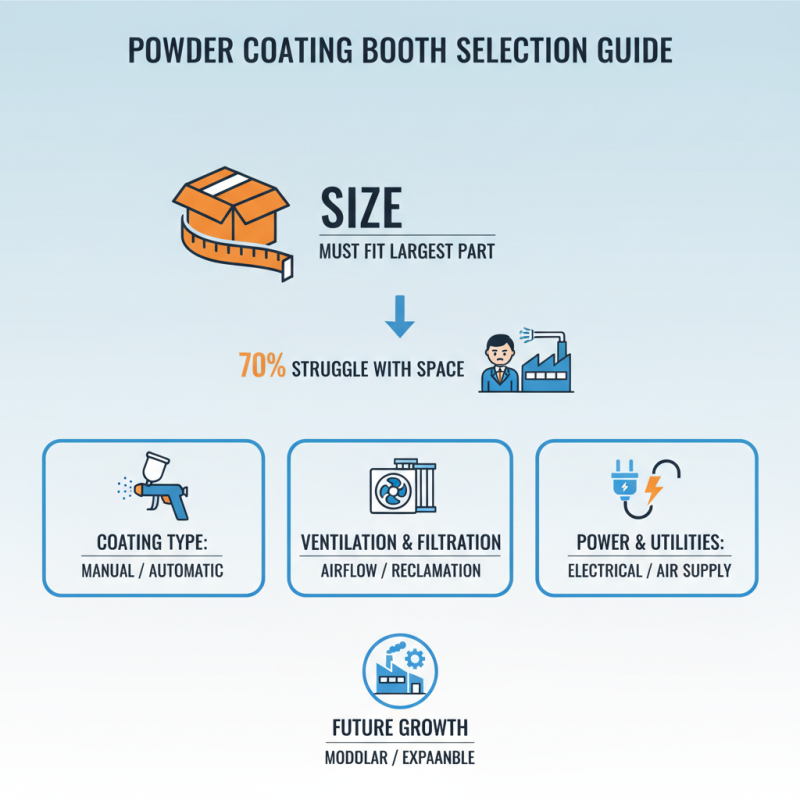

In 2026, various types of powder coating booths are available for businesses. Each type serves different needs. There are both manual and automatic booths. Manual booths allow for hands-on control. They are great for small batches or intricate work. Automatic booths, however, enhance efficiency. They are suitable for larger production runs.

Different designs cater to specific environments. Open front booths are popular for accessibility. They require proper ventilation to ensure safety. Enclosed booths provide better control over dust and contaminants. This is essential in maintaining quality. Some booths feature advanced filtration systems. These systems can capture overspray effectively. It helps to reduce waste, yet, they often require maintenance.

While choosing a booth, reflect on your current needs. Consider your workspace and production volume. Sometimes, businesses overspend on features they don’t need. Budget constraints can lead to difficult decisions. Take the time to evaluate future growth, too. Choosing the right booth can save money in the long run.

2026 Top Powder Coating Booth for Sale Options to Consider

| Booth Type | Size | Price Range | Features | Ideal For |

|---|---|---|---|---|

| Manual Powder Coating Booth | 10' x 10' | $3,000 - $5,000 | Compact design, easy to operate | Small workshops, DIY operations |

| Automated Powder Coating Booth | 15' x 15' | $10,000 - $15,000 | High efficiency, integrated conveyor system | Larger manufacturing facilities |

| Downdraft Powder Coating Booth | 12' x 12' | $8,000 - $12,000 | Enhanced airflow, high-quality finish | Professional shops, high-end applications |

| Crossdraft Powder Coating Booth | 14' x 14' | $7,000 - $11,000 | Versatile airflow, accommodates various sizes | Medium to large jobs, various projects |

Factors to Consider When Choosing a Powder Coating Booth

When selecting a powder coating booth, several crucial factors come into play. Size is one of the primary considerations. A booth must accommodate the largest item you're coating. Research indicates that about 70% of businesses struggle with space issues, underscoring the importance of proper measurements.

Ventilation is another significant aspect. Efficient airflow prevents overspray and ensures a safer work environment. According to the Powder Coating Institute, optimal airflow can reduce hazardous fume accumulation by up to 50%. This statistic highlights the need for diligent planning in airflow design.

Tips: Assess your workspace before making purchases. Consider your workflow and ease of access. Evaluate features such as temperature control. Remember, not every booth fits every operation. Seek options that align with your specific needs. Poor choices may lead to inefficiencies, waste of materials, and higher operational costs.

Key Features of High-Quality Powder Coating Booths

When looking for a top powder coating booth, it's crucial to focus on key features. A well-designed booth provides optimal airflow and ventilation. This helps to ensure even coating and minimizes overspray. High-quality booths also come with durable materials that withstand extensive use. Stainless steel or galvanized metal can be great choices for longevity.

Another aspect to consider is the size of the booth. It should accommodate your projects comfortably. Clutter can lead to mishaps. A spacious environment promotes better workflow. Lighting is essential, too. Proper illumination allows for better visibility when applying powder. Ideal lighting helps you spot imperfections early. It's not just about aesthetics; functional design impacts the final finish.

Lastly, maintenance features are often overlooked. Easy access for cleaning is vital. Your booth should simplify this process, preventing build-up. Having readily available replacement parts can save time and hassle. Ultimately, a thoughtful selection can greatly improve your powder coating process. It's not just about the purchase; it's about enhancing your operation.

Cost Analysis of Different Powder Coating Booth Options

When evaluating powder coating booth options, cost is a critical factor. The range of prices can vary significantly, influenced by booth size, features, and design. According to industry studies, basic booths start at around $5,000. Custom booths can exceed $20,000, depending on specifications. This disparity raises questions about what you truly need versus what is marketed.

Installation costs can add another layer to the budget. Survey data indicates that installation can increase your total expenditure by 15% to 25%. Not all booths come with pre-installed systems, leading some buyers to face unexpected costs. These factors must be weighed carefully.

Maintenance is another long-term cost to factor in. Reports suggest that regular maintenance can account for around 10% of total operational costs annually. Neglecting this can lead to larger expenses down the line. Companies often underestimate these recurring costs, leading to budget constraints later. Identifying an ideal powder coating booth is not just about initial purchase price. It’s about understanding the total cost of ownership.

Future Trends in Powder Coating Booth Technology for 2026

As we approach 2026, the powder coating booth technology landscape is evolving rapidly. One notable trend is the integration of smart technology. These booths now feature sensors for monitoring airflow and temperature. This creates optimal conditions for powder application. However, the reliance on technology can lead to over-dependence. It's essential to maintain manual checks to ensure quality control.

Another trend is sustainability. Eco-friendly materials and energy-efficient designs are gaining traction. Some booths are now equipped with filtration systems that minimize overspray waste. This is a step in the right direction, but companies must continually reassess their environmental impact. The balance between efficiency and sustainability is tricky. While innovations help, routine evaluations are necessary to ensure compliance with environmental standards.

Adaptability also stands out in the future of powder coating booths. With market demands shifting, booths need to be versatile. Modular designs can accommodate various part sizes and shapes. This flexibility can improve production efficiency. However, without proper training, operators might struggle to utilize these features effectively. Addressing this gap is crucial for optimizing the booth's potential.

Related Posts

-

Understanding the Benefits of Powder Coating Equipment for Your Business Growth

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

Top 10 Small Powder Coating Ovens for Efficient Home Use

-

What is Powder Coating Oven and How Does It Work for Your Projects

-

What is Powder Coating Equipment for Sale and How Does It Work?

-

How to Choose the Right Overhead Conveyor System for Your Business Needs