OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

2026 Top Powder Coating Equipment Package Guide for Beginners

As the powder coating industry continues to grow, understanding the powder coating equipment package becomes crucial for beginners. In 2022, the global powder coating market was valued at around $10 billion, with a projected annual growth rate of 5.4% over the next several years. This surge indicates rising demand for durable and eco-friendly finishing solutions.

Investing in the right equipment package can make or break a startup. With various options available, it’s essential to identify what suits your specific needs. Key components typically include spray guns, curing ovens, and recovery systems. Knowing how each piece functions aids in maximizing efficiency. However, budget constraints can lead to hasty decisions, resulting in mismatched equipment.

Many newcomers in the industry face challenges, such as inadequate knowledge or improper equipment usage. Reflecting on these potential pitfalls is vital as it allows for informed choices. By mastering the essential elements of the powder coating equipment package, businesses can position themselves for success in a competitive landscape.

Understanding Powder Coating Basics for Beginners

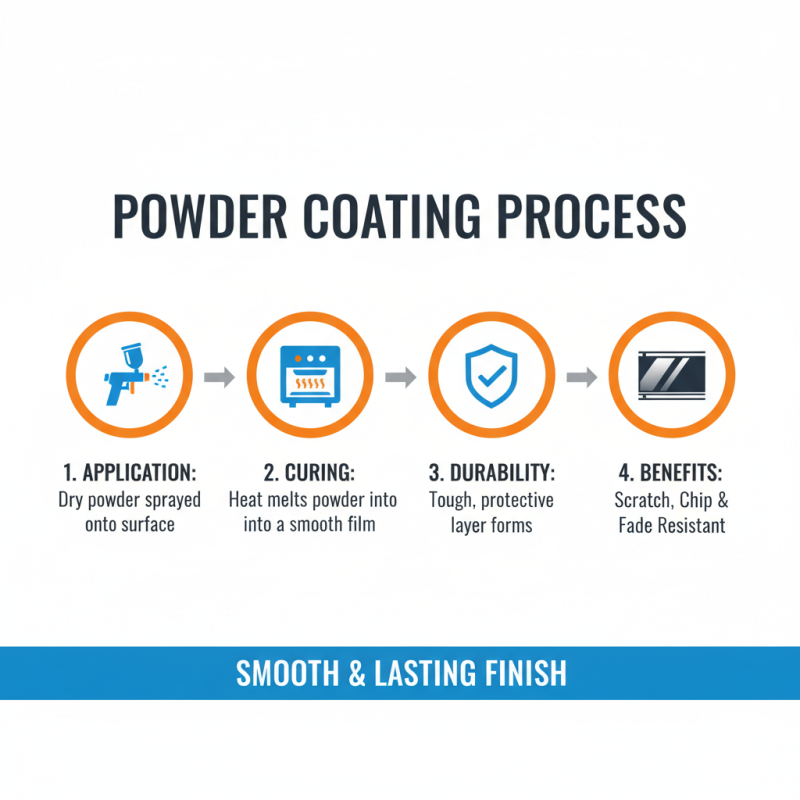

Powder coating is a process that applies a dry powder to surfaces, offering durability and a smooth finish. Unlike traditional painting, it uses a spray gun to apply the powder, which is then cured under heat. This method creates a tough, protective layer resistant to scratches, chipping, and fading. For beginners, understanding the basics is crucial before diving into the equipment needed for this process.

Many people underestimate the importance of preparation. Surface cleaning is essential to achieve a good bond between the powder and the substrate. Ignoring this step can lead to poor adhesion and uneven finishes. Additionally, selecting the right powder type can be challenging. Each powder varies in characteristics and suitable applications. Beginners often find themselves overwhelmed by choices without knowing the specific needs for their projects.

It is also important to understand the curing process. Heat must be properly managed to ensure the powder melts and adheres correctly. This can be tricky, as temperatures that are too high or too low can ruin the final product. Maintaining consistency in temperature and application is vital. Reflecting on these challenges will help beginners refine their skills and avoid common pitfalls in powder coating.

Essential Components of Powder Coating Equipment

Powder coating is a popular finishing process in various industries. It offers durability and a high-quality finish. Essential components of powder coating equipment play a significant role in achieving optimal results. Understanding these components is crucial for beginners.

The first component is the powder coating gun. This device applies the powder to the surface. Electrostatic attraction is used to ensure a uniform coat. According to a 2022 industry report, a well-calibrated gun can improve transfer efficiency. This means less waste and better coverage.

The curing oven is another vital element. It heats the coated items, allowing the powder to melt and adhere. The necessary temperature can vary based on the coating type. An accurate temperature profile can influence coating durability. Industry data indicates that a well-maintained oven ensures consistency, which enhances quality. Errors in temperature settings could lead to uneven finishes, highlighting the need for precision.

The powder recovery system is essential. It collects unused powder for reuse. A quality recovery system can reclaim up to 90% of the powder. However, some designs can become clogged, diminishing efficiency. Regular maintenance is necessary to avoid such pitfalls and ensure smooth operations. Understanding these components helps beginners navigate the powder coating landscape more effectively.

Choosing the Right Powder Coating Equipment Package

Choosing the right powder coating equipment package is crucial for achieving high-quality finishes. Consider your workspace size before purchasing. Compact options work well in small garages, while larger setups fit industrial spaces better. This decision impacts not just the equipment but also your workflow.

Look closely at each component of the package. You need a reliable spray gun, oven, and curing system. Evaluate the coverage the gun provides. Some may spray unevenly, causing wasted materials. Your oven should be able to maintain consistent temperatures. Inconsistent heating can lead to poor adhesion.

Budget is essential, but don't compromise quality. Investing in inferior equipment may require frequent replacements. Think about support and service availability. You'll need assistance if something goes wrong. Reflect on what you truly need versus what looks appealing. Quality tools simplify the process and improve results.

Step-by-Step Guide to Setting Up Powder Coating Equipment

Setting up powder coating equipment can be overwhelming. It involves various components that require careful consideration. First, you'll need a proper space. This area must be well-ventilated and clean. Dust and moisture can ruin the coating process. Consider using a designated room or garage. Ensure it has ample electrical outlets for your machinery.

Next, gather essential tools. A powder coating gun is vital for applying the coating evenly. You might also need a curing oven. This appliance helps solidify the powder, giving it a durable finish. Testing different settings can be tricky. You may not achieve the desired look on the first try. It's okay; experimentation is part of the learning curve. Take notes on what works and what doesn’t.

Lastly, safety is crucial. Wear protective gear, including gloves and goggles. Fumes can be harmful, so a respirator may be necessary. Unexpected issues will arise, and that’s part of the process. Keep a dedicated area for cleanup and disposal of materials. Each mistake is a chance to improve your technique, leading to better results over time.

2026 Top Powder Coating Equipment Package Guide - Equipment Performance Comparison

Common Mistakes to Avoid When Starting Powder Coating

Starting a powder coating business can be rewarding. However, many beginners make common mistakes that hinder their success. For instance, a lack of understanding of equipment is a frequent error. According to industry reports, nearly 40% of new operators do not properly assess their machinery needs. Without the right equipment, achieving uniform finishes can be nearly impossible.

Another mistake involves the importance of surface preparation. Studies indicate that improper prep work is responsible for up to 30% of coating failures. Failing to clean surfaces thoroughly can lead to adhesion issues. Skipping this step may seem like a time-saver, but it often results in costly rework. It is essential to follow a systematic approach to prepare every piece before coating.

Furthermore, many novices overlook the curing process. Each powder coating requires a specific curing temperature and time. Deviating from these guidelines can diminish the coating quality. Reports show that improper curing is one of the top three reasons for customer complaints. Beginners should prioritize mastering these critical aspects to minimize setbacks and improve their overall outcomes.

2026 Top Powder Coating Equipment Package Guide for Beginners - Common Mistakes to Avoid When Starting Powder Coating

| Equipment Type | Common Mistakes | Tips for Beginners |

|---|---|---|

| Powder Coating Gun | Not adjusting the powder flow properly | Start with a lower flow rate and adjust as needed |

| Oven | Inadequate curing time and temperature | Use a thermometer to ensure accurate readings |

| Powder Coating Booth | Poor containment leading to overspray | Ensure proper booth setup to minimize overspray |

| Media Blaster | Using incorrect media for surface prep | Choose the right media based on material and finish |

| Cleaners and Degreasers | Not thoroughly cleaning the substrate | Follow a strict cleaning procedure before coating |

Related Posts

-

Why Choose a Powder Coating Equipment Package for Your Business?

-

How to Choose the Best Powder Coating Equipment in 2026?

-

Understanding the Benefits of Powder Coating Equipment for Your Business Growth

-

2025 Top 5 Powder Coating Equipment for Sale Options You Should Consider

-

Top Powder Coating Equipment Trends to Watch in 2025

-

Top Powder Coating Equipment for Sale Essential Guide for Your Business?