OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

Top 10 Benefits of Conveyor Systems in Modern Industries?

In today’s fast-paced industries, the importance of conveyor systems cannot be overstated. Tony Williams, an expert in automation solutions, emphasizes, “Conveyor systems revolutionize the efficiency of manufacturing processes.” With advancements in technology, these systems streamline operations significantly.

Modern conveyor systems enhance productivity by automating the movement of materials. This reduces manual labor and minimizes the risk of errors. Industries benefit from improved safety and consistent output. Yet, some companies overlook maintenance needs, risking potential downtimes.

Investing in conveyor systems can lead to remarkable returns. However, it also requires careful planning and implementation. Industry leaders must evaluate their specific needs. A one-size-fits-all approach may lead to inefficient systems. In understanding these nuances, businesses can truly harness the advantages that conveyor systems offer.

Benefits of Conveyor Systems in Enhancing Operational Efficiency

Conveyor systems significantly enhance operational efficiency in modern industries. They streamline material handling and reduce manual labor. With the ability to move products quickly, businesses can increase productivity. This speed mitigates delays in the production process, allowing for a smoother workflow.

However, not every implementation is flawless. Overreliance on automated systems can lead to neglect in employee training. Workers might lose critical skills, and this could affect overall performance. Moreover, regular maintenance is essential. Without it, conveyor systems can face unexpected downtimes, disrupting the operations they are meant to improve.

Integration with existing systems can be a challenge. Companies must ensure compatibility to avoid bottlenecks. Continuous monitoring and adjustments are necessary. Balancing technology with human oversight creates a more resilient operation. Emphasizing this balance leads to a more sustainable growth path in the long run.

Improving Workplace Safety Through Automated Conveyor Solutions

Automated conveyor systems significantly enhance workplace safety across various industries. A study from the Occupational Safety and Health Administration (OSHA) reveals that over 40% of workplace injuries are related to manual material handling. By integrating conveyor solutions, companies can reduce these risks considerably. Conveyors minimize the need for employees to lift heavy loads, thereby lowering the chances of musculoskeletal injuries.

Moreover, automated systems streamline operations. They allow for seamless material flow, reducing clutter in workspaces. A report by the National Safety Council indicates that organized workplaces can cut accidents by up to 25%. However, safety protocols must be in place to ensure proper machine usage. Employees require training to operate conveyor systems effectively, as improper use can lead to dangerous situations, such as entrapments.

While conveyor systems offer numerous advantages, they are not foolproof. Maintaining equipment properly is crucial to prevent breakdowns that can lead to accidents. Regular inspections and maintenance checks are essential. Implementing these measures can enhance the safety benefits of conveyor systems in modern industries.

Top 10 Benefits of Conveyor Systems in Modern Industries

This chart illustrates the top 10 benefits of conveyor systems in modern industries, highlighting their crucial roles in improving efficiency, safety, and overall productivity.

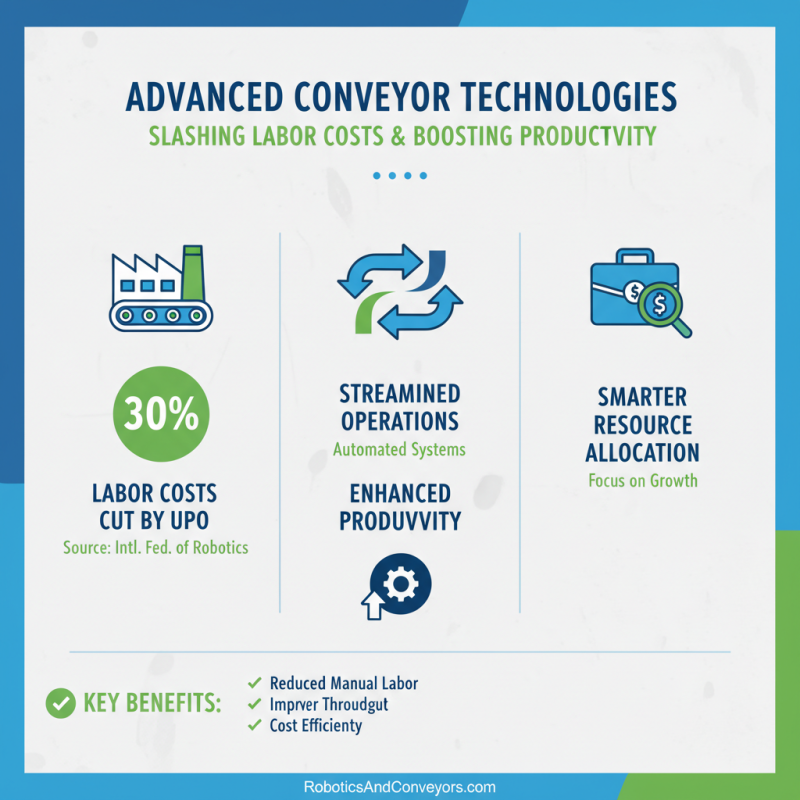

Reducing Labor Costs with Advanced Conveyor Technologies

Advanced conveyor technologies are transforming industries by significantly reducing labor costs. According to a recent report by the International Federation of Robotics, labor costs can be cut by up to 30% when integrating automated conveyor systems. These systems streamline operations and enhance productivity, allowing businesses to allocate resources more effectively.

Automation with conveyor systems minimizes human error, leading to more consistency in product handling. A study by the Material Handling Industry of America stated that automated systems improve operational efficiency by as much as 50%. This not only leads to reduced labor costs but also maximizes output. However, companies must evaluate the initial investment versus long-term savings.

Tips: Start small. Assess your current processes to identify areas where automation could help. Engage your team in discussions about potential improvements. Periodic reviews of your conveyor performance will highlight areas needing adjustment. Remember, adapting technology is not a one-time task but an ongoing journey.

Versatility of Conveyor Systems Across Various Industries

Conveyor systems have transformed various industries, providing essential versatility. In manufacturing, they enhance efficiency by streamlining processes. According to a report from the Conveyor Equipment Manufacturers Association, nearly 40% of all material handling involves conveyor systems. This statistic underlines their importance in ensuring smooth production flows.

In the food industry, conveyor systems adapt to diverse tasks. They move products swiftly while maintaining hygiene standards. The International Food and Beverage Industry report states that over 60% of food processing plants utilize conveyor systems for packaging and assembly. This trend showcases their effectiveness and reliability in environments demanding strict cleanliness.

Logistics and warehousing also benefit significantly. Conveyor belts enable rapid sorting and distribution, reducing operational gaps. A survey highlighted that companies can see productivity boosts of up to 30% when implementing conveyor technology. However, maintenance can become a challenge. Downtime for repairs can disrupt workflow. Balancing cost-effectiveness with reliability remains essential for industry operators.

Top 10 Benefits of Conveyor Systems in Modern Industries

| Benefit | Description | Industry Examples | Efficiency Improvement (%) |

|---|---|---|---|

| Increased Efficiency | Automates the movement of goods, reducing manual labor. | Manufacturing, Warehousing | 30% |

| Enhanced Safety | Minimizes risks associated with manual handling. | Construction, Mining | 25% |

| Space Optimization | Compact setup compared to traditional transport methods. | Food Processing, Retail | 20% |

| Cost Reduction | Decreases labor costs and improves productivity. | Logistics, Manufacturing | 15% |

| Flexibility | Adaptable to various types of goods and production lines. | Automotive, Electronics | 18% |

| Improved Accuracy | Reduces errors in order fulfillment and inventory management. | E-commerce, Retail | 22% |

| Reduced Downtime | Streamlines processes to minimize idle time. | Pharmaceuticals, Heavy Machinery | 10% |

| Sustainability | Optimizes energy use and reduces waste in operations. | Green Technology, Logistics | 12% |

| Product Movement Speed | Increases speed of transporting goods from one point to another. | Food & Beverage, Manufacturing | 35% |

| Integration with Technology | Easily integrates with automated systems and IoT. | Warehouse Automation, Distribution | 20% |

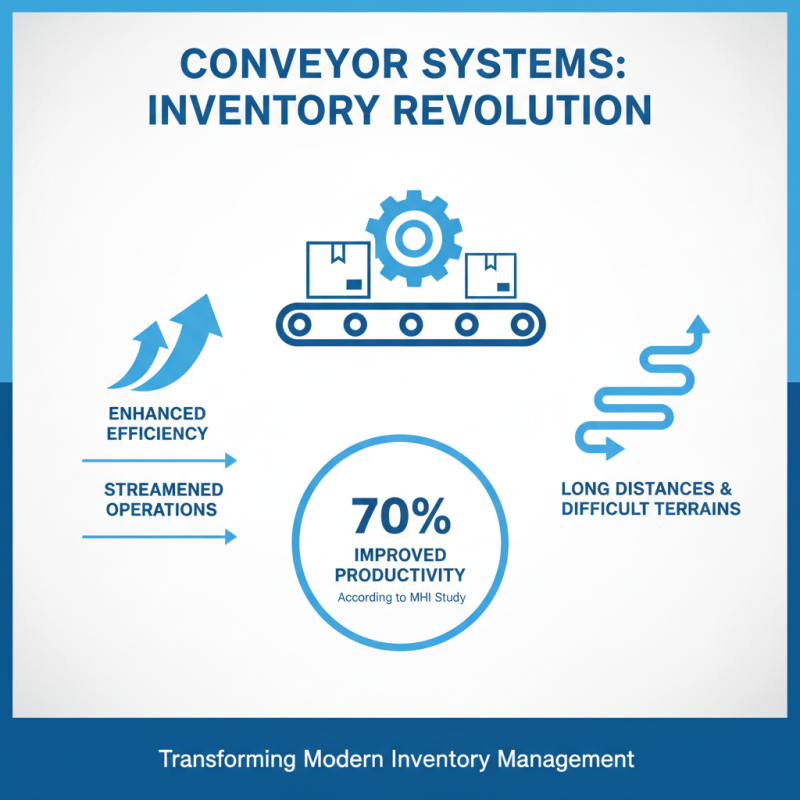

Streamlining Inventory Management and Product Handling with Conveyors

Conveyor systems have transformed inventory management in modern industries. They enhance efficiency and streamline operations. These systems can move materials over long distances and difficult terrains. According to a recent study by the Material Handling Industry of America, 70% of companies report improved productivity after implementing conveyor systems.

When it comes to product handling, the benefits are clear. Conveyors reduce manual labor, minimizing the risk of injury. They also enable faster processing times. In warehouse environments, utilizing conveyors can cut order-picking times by up to 30%. However, companies sometimes overlook maintenance issues. Neglecting regular checks can lead to unexpected downtimes.

Moreover, integrating conveyor systems promotes better space utilization. This is crucial when dealing with limited warehouse areas. A study by the Warehousing Education and Research Council revealed that warehouses utilizing conveyor systems can optimize storage space by 25%. Yet, not every implementation is seamless. Challenges in initial setup and configuration can arise. Continuous adaptation and training are necessary for a smooth transition.

Related Posts

-

2025 Top 5 Conveyor Systems Innovations Transforming Industry Efficiency

-

What is Powder Coating Oven and How Does It Work for Your Projects

-

Understanding the Benefits of Powder Coating Equipment for Your Business Growth

-

2026 Top Powder Coating Booth for Sale Options to Consider?

-

The Ultimate Guide to Choosing the Perfect Small Paint Booth for Your Projects

-

Top Spray Booths for Sale in 2025 Find the Best Options Available Now