OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

Top 10 Benefits of Using Used Powder Coating Oven for Your Business

In the competitive landscape of powder coating, businesses continuously seek cost-effective solutions. A used powder coating oven can be a game-changer. According to industry expert David Brown, “Opting for a used powder coating oven can maximize efficiency while reducing costs.”

Many companies hesitate to invest in second-hand equipment. They worry about performance and reliability. However, a well-maintained used powder coating oven often offers exceptional value. Imagine the savings on initial investment, all while achieving high-quality finishes. A used oven may require some refurbishment, but with the right care, it can perform as well as new models.

Embracing this option also encourages sustainability. Purchasing used equipment reduces waste and promotes recycling. This choice speaks volumes about a company's commitment to the environment. Thus, a used powder coating oven not only enhances productivity but also positively impacts our planet. In today's economy, such considerations are vital for success.

Understanding the Concept of Used Powder Coating Ovens

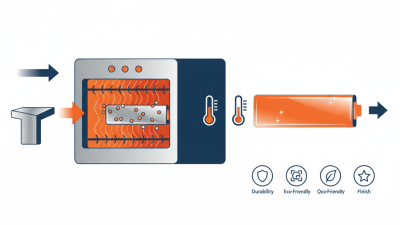

Understanding used powder coating ovens can enhance your business operations. These ovens are designed to apply a durable finish to metal surfaces. They utilize heat to cure powder coating, creating a tough, protective layer. It's important to note that quality can vary. Not all used ovens will function optimally. Diligence in selection is key.

Used powder coating ovens can save you significant costs. New ovens often come with high price tags. A well-maintained used oven can perform almost as well as a new one. However, thorough inspection is necessary. Look for signs of wear or damage. Maintenance records can provide valuable insight into previous usage.

Using a used oven may require some adjustments. Technology may vary from newer models. You might need to adapt your processes. Training staff can also be a challenge. They may need to learn new operating methods. Yet, the savings and efficiency gains can outweigh these challenges.

Cost-Effectiveness of Investing in Used Powder Coating Ovens

Investing in used powder coating ovens is a smart choice for many businesses. These ovens can significantly reduce operational costs. Since new equipment can be pricey, opting for pre-owned units allows companies to save money immediately. Many used ovens still have plenty of life left in them.

Cost-effectiveness is not just about the purchase price. Maintenance and repairs are typically lower with used equipment. This factor can lead to further savings. Companies should assess the condition of used ovens before buying. Sometimes, they might require a bit of work to get them running optimally.

Tips: Always check the oven's history. Request service records if possible. This information can reveal potential issues. Look for warranties on used ovens, too. A warranty can provide peace of mind for any future concerns. Also, analyze energy efficiency ratings. Older models might consume more energy, leading to higher bills. Even a used oven can have hidden costs if not critically evaluated.

Environmental Benefits of Reusing Industrial Equipment

Reusing industrial equipment, like powder coating ovens, offers significant environmental benefits. By choosing used ovens, businesses contribute to reducing waste. These ovens often have a long lifespan, providing valuable service without the need for new manufacturing processes. This leads to less energy consumption and lower emissions linked to production.

Tips: Always check the condition of used equipment. Look for signs of wear and tear. A visually appealing oven might hide deeper issues. Regular maintenance can enhance its lifespan. Also, consider the installation process. Proper setup is crucial to ensure efficient operation.

Using secondary markets for equipment is an excellent choice. It lessens the demand for new materials. The environmental impact is evident, yet many overlook it. Transforming equipment life cycles can create a more sustainable business. It promotes a circular economy, which is vital for our planet's health. Each choice matters. Ensure the choices you make reflect your dedication to sustainability.

Top 10 Benefits of Using Used Powder Coating Oven for Your Business

Improved Efficiency in Production Processes with Used Ovens

Using a used powder coating oven can significantly improve the efficiency of production processes. In fact, research indicates that powder coating systems can reduce energy consumption by up to 30%. This can directly benefit businesses looking to lower operating costs. Efficient ovens also lead to faster curing times. For example, some used ovens have the capability to cure coatings within 15-20 minutes, compared to older models that take much longer.

The versatility of used powder coating ovens makes them appealing. They can handle various substrates and coating types. This adaptability allows businesses to expand their product offerings. Increased production agility is a crucial advantage in competitive markets. However, it is important to consider the maintenance history of used ovens. Proper evaluation can prevent potential downtime and issues later on.

Moreover, the initial investment cost for used ovens is typically lower than new models. According to industry reports, many businesses report savings upwards of 40% when opting for used equipment. Yet, companies should not overlook the need for skilled staff to operate these ovens effectively. Without the right training, operational efficiency may suffer. Balancing cost savings and operational requirements is vital for long-term success.

Understanding Maintenance and Longevity of Used Powder Coating Ovens

When considering used powder coating ovens, maintenance is key. Regular checks are essential for optimal performance. A well-maintained oven can last for many years. However, neglecting maintenance can shorten its lifespan significantly. Dust buildup can clog filters and affect airflow. This leads to uneven coating and wasted materials.

Longevity also depends on how the oven is used. Consistent high temperatures stress the components. If not monitored, this may cause premature failures. Operators should keep an eye on temperature fluctuations. It's not uncommon to overlook small signs of wear and tear. Addressing these promptly prevents bigger issues later on.

Additionally, the quality of the previous usage matters. An oven that was used in a dusty environment may require more frequent cleaning. On the other hand, one maintained well can save costs over time. Yet, users often assume all ovens are in equal condition. This can be a costly mistake if overlooked. Proper assessment and routine care can enhance the lifespan of a used oven significantly.

Related Posts

-

10 Essential Tips for Choosing a Used Powder Coating Oven for Your Business

-

Top 10 Small Powder Coating Ovens for Efficient Home Use

-

Exploring the Future of Surface Finishing with Innovative Powder Coating Equipment for Sale

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

What is Powder Coating Oven and How Does It Work for Your Projects

-

How to Choose the Best Powder Coating Equipment in 2026?