OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

The Best Paint Booths for Professional Automotive Finishing and DIY Projects

In the automotive finishing industry, the importance of a quality paint booth cannot be overstated. As John Smith, an industry expert with over two decades of experience, emphasizes, “A good paint booth is the heart of every successful paint job.” This statement rings true for both professionals and DIY enthusiasts alike.

Choosing the right paint booth can be challenging. Each project demands a different approach, and the options can be overwhelming. From size and airflow to lighting and filtration, every detail matters. A well-ventilated paint booth enhances the application process while ensuring safety. Yet, many overlook how inadequate environments can ruin a perfect finish.

Consider a common scenario: using a subpar booth on an intricate project. The result often leads to flaws like dust particles ruining the paint surface or uneven coats. These mishaps can be frustrating and costly, highlighting the need for careful selection. Each choice shapes the outcome of the work. A thoughtful decision on the right paint booth can make all the difference.

Understanding Paint Booths: Types and Features for Automotive Finishing

When exploring paint booths for automotive finishing, understanding the different types and features is essential. There are down-draft booths, cross-draft booths, and semi-downdraft options. Each type offers unique airflow and temperature control. A well-designed booth maintains a clean environment, reducing dust and debris. Ideal for both professionals and DIY enthusiasts, the right booth can enhance the finished product.

Features to consider include lighting, filtration, and size. Bright, even lighting helps identify imperfections. A good filtration system captures overspray, protecting both the environment and the user. However, larger booths may seem daunting for home projects. It’s important to evaluate the available space. Not all booths are user-friendly; some require skill to operate efficiently. Mistakes can happen, like overspray or uneven coats. Learning from these challenges is part of the process.

Creating a comfortable workspace is crucial. Ventilation keeps the air fresh, while temperature control influences drying times. Budget constraints often limit choices. A smaller booth may compromise results but could fit tighter budgets. Even with limitations, finding the right paint booth can boost your project’s quality, revealing the intricate details in your work.

The Best Paint Booths for Professional Automotive Finishing and DIY Projects

| Booth Type | Size (ft) | Airflow (CFM) | Filter Type | Noise Level (dB) | Price Range ($) |

|---|---|---|---|---|---|

| Downdraft | 10 x 20 | 3000 | HEPA | 75 | 5000 - 7000 |

| Crossdraft | 12 x 24 | 4000 | Paint Arrestor | 72 | 4000 - 6000 |

| Semi-Downdraft | 14 x 30 | 3500 | Multi-Stage | 70 | 6000 - 8000 |

| Portable | 8 x 12 | 1500 | Disposable | 68 | 1000 - 2000 |

| Enclosed | 20 x 30 | 5000 | Carbon Filter | 76 | 8000 - 10000 |

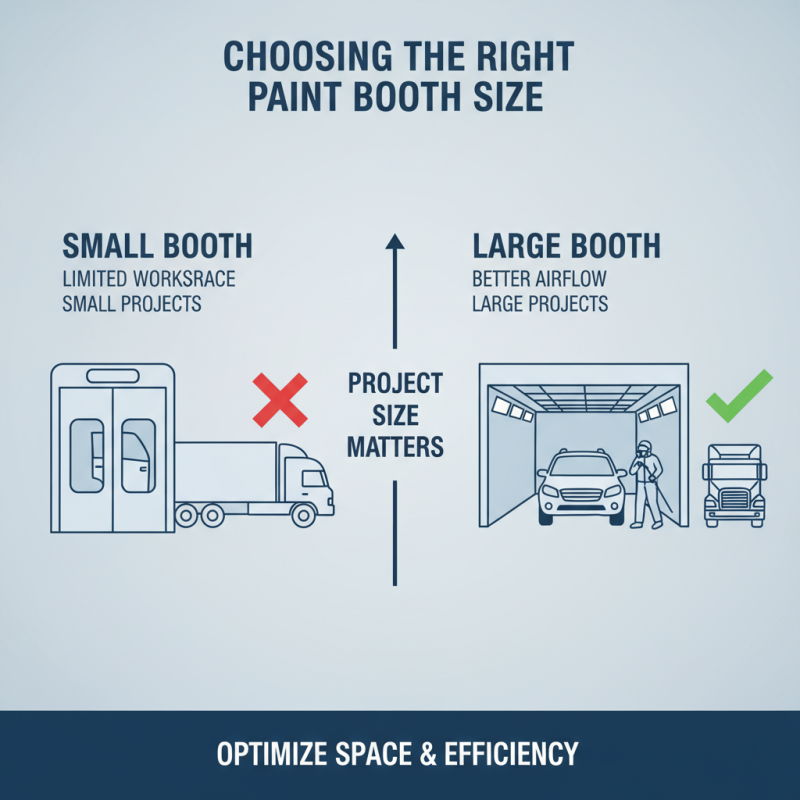

Choosing the Right Paint Booth Size for Your DIY and Professional Needs

Choosing the right paint booth size is essential for both professional and DIY projects. A small booth may seem convenient, but it can limit your workspace. If you're tackling larger vehicles, a bigger booth is necessary. It allows for better airflow and easier movement around the project. For smaller projects, a compact setup can suffice, but keep in mind the constraints it brings.

You must also consider ventilation. A booth that’s too small may not provide adequate airflow. This can lead to poor paint application and require multiple touch-ups. On the other hand, an oversized booth may waste energy and resources. It's crucial to find a balance that meets your specific needs.

Reflecting on past experiences can offer insight. Often, DIY enthusiasts underestimate the space required. A project may grow in complexity, demanding more room than initially planned. Learning from these situations can guide you in selecting the proper size. Evaluating your typical projects helps you avoid future hurdles.

Key Features of High-Quality Automotive Paint Booths

A high-quality automotive paint booth is essential for achieving professional results. These booths ensure controlled environments where dust and contaminants are minimized. Key features include appropriate airflow, adequate lighting, and temperature control. Studies show that a well-ventilated booth can reduce defects by up to 75%.

Airflow is crucial. It keeps the spray area clean and improves paint adhesion. Look for a booth with efficient exhaust systems that comply with safety standards. Displacement of air should be around 100 feet per minute for optimal performance. Inadequate airflow can lead to uneven finishes.

Lighting is often overlooked. Proper illumination helps ensure consistent coverage. LED lighting with a color temperature of around 5000 Kelvin mimics daylight and enhances visibility. Remember, shadows can hide flaws. Inspect your work under different lighting conditions to catch any imperfections.

Tip: Test spray patterns on scrap material before starting your main project. This helps avoid mistakes and saves time. Additionally, consider the size of the booth. It should accommodate your projects comfortably, without crowding. A cramped space invites errors. Aim for balance; a booth too large might waste resources, while one too small restricts creativity.

Safety Considerations When Using a Paint Booth

When using a paint booth, safety should always come first. Reports indicate that nearly 30% of paint-related injuries occur due to improper ventilation. A well-ventilated booth can minimize exposure to harmful fumes. Install exhaust fans to direct vapors outside. It's essential to choose the right filters to trap particulates and maintain air quality.

Personal protective equipment (PPE) is crucial. Many workers overlook this aspect. Wearing gloves, masks, and goggles can significantly reduce health risks. Studies show that inadequate PPE increases the chance of chemical exposure. Be mindful of the materials used in the paint, as some can be more hazardous than others. Regular training on proper safety protocols can help keep workers informed and protected.

Monitoring environmental conditions is another key factor. Humidity and temperature can impact paint application. Too much humidity can lead to improper curing. Yet, many overlook this detail; it can result in unsatisfactory finishes. Conduct routine checks with reliable instruments. Awareness of your surroundings enhances overall safety and project quality. Staying proactive about these elements can save time and resources in the long run.

Maintenance Tips for Longevity of Your Paint Booth

Maintaining a paint booth is crucial for any automotive enthusiast or professional. Regular cleaning ensures that dust and debris do not compromise your paintwork. Perform light clean-ups daily. Use a vacuum or a damp cloth to wipe surfaces. This helps in maintaining a good environment for painting.

Pay attention to the booth's lighting. Over time, lights may dim or flicker, affecting visibility. Replace bulbs as needed to ensure consistent lighting. Also, monitor the humidity levels inside the booth. High humidity can ruin paint adhesion and finish quality. Invest in a reliable dehumidifier, especially in moist climates.

Check the filter systems regularly. Dirty filters can lead to poor air quality and affect the curing process. Change filters as per the manufacturer's recommendations. Reflect on your booth's airflow too. If it feels sluggish, there may be an underlying blockage. Taking these steps will enhance the efficiency of your paint booth and improve your overall painting experience.

The Best Paint Booths for Professional Automotive Finishing and DIY Projects

This chart illustrates the average ratings of different types of paint booths based on user feedback for professional automotive finishing and DIY projects.

Related Posts

-

The Ultimate Guide to Choosing the Perfect Small Paint Booth for Your Projects

-

Why You Should Consider Buying a Paint Booth for Sale for Your Business

-

Top 7 Portable Paint Booths for Efficient Home Painting Projects

-

Understanding the Benefits of Powder Coating Equipment for Your Business Growth

-

Top 10 Paint Booths for Sale You Need to Consider for Your Business

-

What is an Overhead Conveyor and How Does It Benefit Your Business?