OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

Why Choose a Powder Coating Equipment Package for Your Business?

In today's competitive market, choosing the right equipment is crucial for success. A powder coating equipment package can elevate your business's capabilities. This package offers various features that enhance efficiency, quality, and profitability.

Investing in a powder coating equipment package means gaining reliable machinery. It provides consistent results and improves production speed. However, not all packages are created equal. Some may fall short on durability or efficiency. Thus, careful research is essential before making a decision.

The right equipment can influence the overall workflow. Poor choices lead to wasted resources and time. Reflect on your business needs. Analyze if you require advanced options or can start with basic tools. Remember, the ultimate goal is to streamline operations while delivering exceptional products.

Benefits of Powder Coating Equipment for Businesses

Powder coating equipment is becoming increasingly important for businesses. This technology offers a durable finish, making products resistant to scratches, chips, and fading. According to industry reports, the powder coating market is expected to reach $15 billion by 2026, growing because of these advantages.

Businesses can significantly reduce waste. Traditional liquid coatings often generate overspray, which can be about 30%. In contrast, powder coating can achieve up to 98% transfer efficiency. This efficiency not only cuts costs but also minimizes the environmental footprint. Additionally, the curing process of powder coating uses significantly less energy compared to liquid alternatives.

Tip: Regular maintenance of your equipment can enhance performance. Check for clogged nozzles and ensure the right temperature settings are maintained.

Many see powder coating as environmentally friendly. Solvent emissions are lower, making it a safer choice. However, some companies still face challenges with the initial investment. While upfront costs may seem high, the long-term savings on materials and energy can offset this.

Tip: Consider financing options to manage initial costs.

Investing in powder coating equipment can redefine your business's efficiency. While it’s advantageous, keeping an eye on industry trends is essential. This proactive approach can help in reevaluating operational strategies effectively.

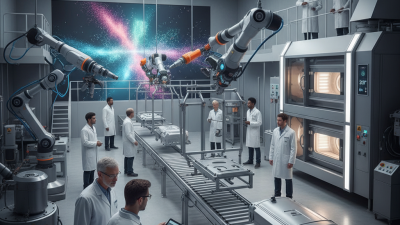

Key Components of a Powder Coating Equipment Package

When considering a powder coating equipment package, understanding its key components is crucial. A comprehensive system typically includes a spray booth, curing oven, and recovery unit. Each of these parts plays a vital role in ensuring high-quality finishes. The spray booth provides a controlled environment for applying powder. Studies indicate that optimal booth design can improve transfer efficiency by over 90%. This statistic highlights the importance of selecting the right booth.

The curing oven is equally significant in achieving durable coatings. Precise temperature control is necessary for proper curing. Data shows that inconsistency in oven performance can lead to 15-20% increased defects in coatings. This not only affects the aesthetic quality but can also shorten the lifespan of the finished product. Investing in an efficient oven improves both quality and customer satisfaction.

Lastly, the recovery unit helps minimize waste. This component collects excess powder for reuse. Reports indicate that effective recovery systems can reduce powder waste by up to 30%. However, many companies overlook the potential energy costs associated with running these systems. Evaluating these elements can guide businesses in making informed choices about their equipment needs.

Cost-Effectiveness of Investing in Powder Coating Solutions

Investing in powder coating solutions offers significant cost-effectiveness for businesses. These systems reduce material waste and application costs. Unlike traditional methods, powder coating allows for the reuse of overspray. This aspect can lead to noticeable savings over time. Businesses often see a quicker return on investment compared to other coating methods.

Moreover, the durability of powder coatings can reduce long-term maintenance costs. If a finish lasts longer, there will be fewer reapplications needed. Shorter downtime during production can also result. A well-implemented powder coating process can streamline operations. However, it does require initial training and adjustments. Mistakes can happen during the learning phase, which may affect the budget.

Choosing the right equipment is essential. Some might underestimate the importance of quality controls. Investing in adequate training is necessary for staff to use the equipment effectively. In the long run, these expenses can pay off. Evaluating initial costs alongside potential savings helps create a clearer picture. Thus, while challenges exist, the overall benefits are compelling.

Applications and Industries That Benefit from Powder Coating

Powder coating is beneficial across various industries. Manufacturers in automotive, aerospace, and appliance sectors rely on this technology. It provides a durable finish that withstands harsh conditions. The process involves applying a dry powder that is cured under heat. This results in a tough and attractive surface.

Furniture makers also take advantage of powder coating. It offers a wide range of colors and textures. This flexibility allows for creative design possibilities. In addition, outdoor furniture gains superior weather resistance. However, some users may struggle with consistency in coating thickness. It can be a learning curve for those new to the process.

Construction and architectural industries benefit significantly. Metal structures and components are often powder coated for enhanced aesthetics. This method reduces the emissions that standard painting techniques produce. Yet, achieving the right balance in finish can be challenging. Users sometimes overlook the importance of surface preparation. Without proper prep work, even the best equipment may not deliver.

Why Choose a Powder Coating Equipment Package for Your Business? - Applications and Industries That Benefit from Powder Coating

| Industry | Applications | Benefits of Powder Coating | Typical Equipment Used |

|---|---|---|---|

| Automotive | Vehicle frames, wheels, and engine components | Durability, corrosion resistance, and colorful finishes | Powder Coating Gun, Curing Oven |

| Architectural | Railings, windows, and doors | Weather resistance, aesthetic appeal, and eco-friendliness | Batch Ovens, Powder Booths |

| Furniture | Metal furniture, lighting fixtures, and decor | Versatile finishes, scratch resistance, and easy cleaning | Electrostatic Powder Coating Equipment |

| Industrial Equipment | Machinery parts, tools, and frames | Increased lifespan and reduced maintenance costs | Conveyor Systems, Curing Ovens |

| Electronics | Casing for appliances and devices | Thermal stability, insulation, and aesthetic options | Powder Coating Equipment, Drying Ovens |

Choosing the Right Supplier for Powder Coating Equipment Packages

Choosing the right supplier for powder coating equipment packages is crucial for any business. A report from the Powder Coating Institute states that the global powder coating market is expected to reach $23.5 billion by 2025. This growth reflects the increasing demand for efficient and eco-friendly coating solutions. Selecting a reputable supplier can significantly impact operational efficiency and product quality.

When evaluating suppliers, consider their experience and customer feedback. A well-established supplier with a proven track record can offer insights into technology trends. Additionally, check for client testimonials and case studies. According to industry analysis, companies that invest in reliable equipment tend to improve their production rate by 30%. However, it is essential to ask about after-sales support, as this can influence long-term satisfaction.

Not all suppliers provide the same level of service. Some may promise quick delivery yet fail to meet deadlines. Others might lack comprehensive training programs for equipment use. It’s important to have a clear understanding of warranty terms and maintenance services. A reliable supplier should offer transparent communication. If communication feels rushed or unclear, that’s a red flag. Taking time to choose wisely may save headaches later.

Related Posts

-

Top Powder Coating Equipment Trends to Watch in 2025

-

How to Choose the Best Powder Coating Equipment in 2026?

-

Understanding the Benefits of Powder Coating Equipment for Your Business Growth

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

2025 Top 5 Powder Coating Equipment for Sale Options You Should Consider

-

Top Powder Coating Equipment for Sale Essential Guide for Your Business?