OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

How to Choose the Best Powder Coating Equipment in 2026?

As the powder coating industry evolves, selecting the right powder coating equipment becomes increasingly crucial. Industry expert James Thompson once stated, "Quality equipment can set you apart in this competitive market." His insight emphasizes the significance of informed choices in a rapidly changing landscape.

In 2026, various options will dominate the market. Numerous brands and models will vie for attention. Navigating this sea of choices requires careful consideration of several factors. The equipment not only impacts efficiency but also affects the durability of the final product. Each detail, from spray guns to curing ovens, plays a vital role.

When evaluating powder coating equipment, think about your specific needs. What's your project scale? Do you prioritize speed or finish quality? Reflect on your production context to ensure you make the best investment. Balancing cost with efficiency isn't always straightforward. Consider the long-term performance versus the immediate price tag.

Factors to Consider When Choosing Powder Coating Equipment

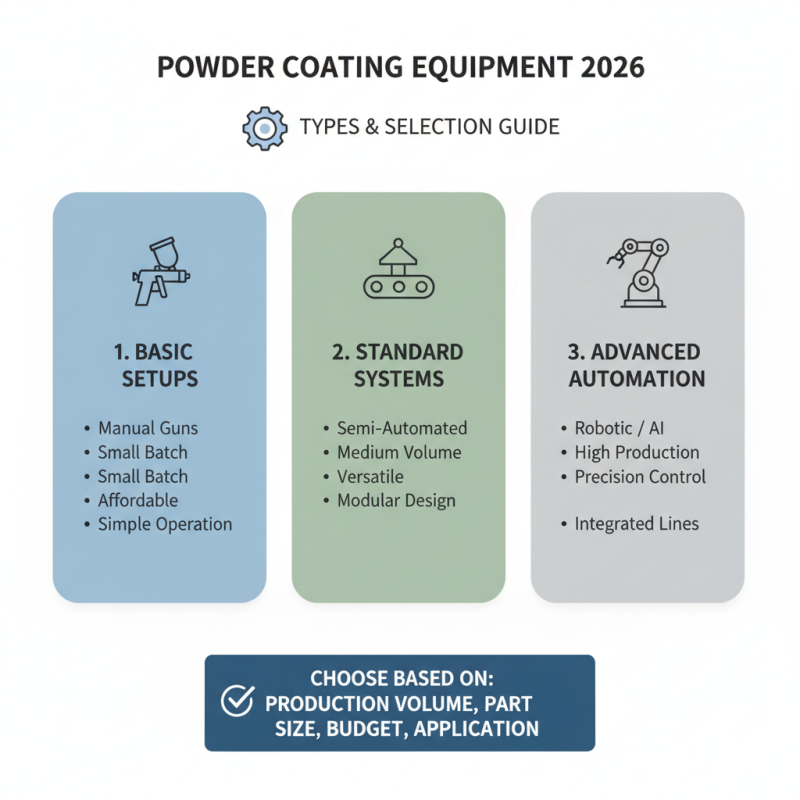

Choosing the right powder coating equipment in 2026 involves evaluating several critical factors. Start with the equipment type. Various options exist, from manual to fully automated systems. Each has its pros and cons. Manual systems can save costs but may require more labor. Automated systems enhance efficiency but often come with higher upfront costs.

Another essential consideration is capacity. Understand your production needs. If your facility is small, a compact setup may suffice. Larger operations require high-capacity systems. Think about the future too. Your equipment should accommodate growth, preventing frequent upgrades.

Don't overlook compatibility. Ensure the equipment suits the materials you plan to coat. Different powders have unique requirements. Inadequate equipment can lead to poor adhesion and finish quality. Testing equipment before full-scale use can prevent costly mistakes. Regular maintenance is also crucial, yet often neglected. Keeping your equipment in good shape ensures consistent performance and reduces downtime.

Types of Powder Coating Equipment Available in 2026

When selecting powder coating equipment in 2026, understanding the types available is crucial. Various options cater to different needs. Equipment ranges from basic setups to advanced systems, each tailored for specific applications.

Electrostatic spray guns are popular. They provide a controlled method for applying powder. Users can achieve a uniform coating with minimal waste. However, setup and maintenance can be challenging. Regular cleaning is essential. Ignoring it can lead to uneven finishes.

Another option is the fluidized bed. This method preheats parts before coating. It results in a thicker layer. While effective, it can require significant space and energy. Not every shop has that. It’s vital to assess your workspace and energy capabilities.

Tips: Always test equipment before purchase. This ensures it meets your production needs. Also, consider the technical support available. A well-informed team can make a difference. Evaluate each machine's durability. Investing now can save costs later.

Evaluating the Technical Specifications of Powder Coating Machines

When evaluating the technical specifications of powder coating machines, key factors are performance and efficiency. In a 2023 industry report, top-performing machines achieved an application efficiency rate of over 90%. This is significant. High efficiency reduces material waste, ultimately saving costs and enhancing productivity.

Consider the heart of the machine: the spray gun. Advanced powder coating systems now feature guns with high transfer efficiency (HTE) technology. These models can deliver up to 70% transfer efficiency. This means more powder adheres to the item, reducing overspray and improving surface finish quality.

Moreover, temperature control is critical. Ideal curing temperatures range from 350°F to 400°F. Machines that offer precise temperature monitoring ensure better crosslinking. Neglecting this can lead to poor adhesion and finish. It is crucial to balance technology features with user-friendliness. Complicated interfaces can pose a challenge. Manufacturers often overlook simplicity, which can affect the learning curve for new operators.

How to Choose the Best Powder Coating Equipment in 2026? - Evaluating the Technical Specifications of Powder Coating Machines

| Specification | Value |

|---|---|

| Type of Equipment | Electrostatic Powder Coating Gun |

| Maximum Output Voltage | 100 kV |

| Powder Feed Rate | 150 g/min |

| Compressed Air Requirement | 4-6 bar |

| Weight | 2.5 kg |

| Control Type | Digital Control System |

| Warranty Period | 3 Years |

| Price Range | $2,000 - $5,000 |

Assessing Cost vs. Performance in Powder Coating Equipment

When choosing powder coating equipment, balancing cost and performance is essential. Industry reports indicate that the average investment for high-performance systems ranges from $30,000 to $100,000. This can be daunting for many businesses. However, investing in quality equipment often leads to increased efficiency and less waste.

Tips: Consider your production volume. If low, a more modest system may suffice. Higher demands usually justify additional spending.

Performance should never be overlooked. Equipment with advanced features enhances coating adhesion and finish quality. Data suggests that machines with better electrostatic capabilities can improve coverage by 20-30%. Nevertheless, not all companies need such advanced features. Reflect on your specific needs before opting for premium options.

Tips: Assess the total cost of ownership. Factor in maintenance and energy consumption over time. It may reveal more about long-term value than the initial purchase price. Find a balance that doesn’t sacrifice quality for savings.

Maintenance and Support for Powder Coating Equipment Choices

When selecting powder coating equipment, maintenance and support are key factors. Regular upkeep ensures longevity and efficiency. Consider having a maintenance schedule in place. Equipment often needs calibration and cleaning. These small tasks can prevent larger issues from arising.

Support is equally important. Look for suppliers that offer reliable customer service. A responsive team can help solve problems quickly. Check if they provide comprehensive manuals and online resources. This can ease the learning curve. Equipment can sometimes fail unexpectedly. Having a solid support system will mitigate production downtime.

Don't overlook the importance of training. Even the best equipment needs skilled operators. Ensure your team is familiar with both usage and maintenance. Investing in training can yield long-term benefits. Reflect on your current capabilities and identify gaps. Improvements in training and support can lead to enhanced powder coating outcomes.

Related Posts

-

2025 Top 5 Powder Coating Equipment for Sale Options You Should Consider

-

Understanding the Benefits of Powder Coating Equipment for Your Business Growth

-

10 Essential Tips for Choosing a Used Powder Coating Oven for Your Business

-

Top Powder Coating Equipment Trends to Watch in 2025

-

The Ultimate Guide to Choosing the Best Mobile Paint Booth for Your Business Needs

-

What is an Overhead Conveyor and How Does It Benefit Your Business?