OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

How to Choose the Right Conveyor Systems for Your Business?

Choosing the right conveyor systems for your business can significantly impact efficiency and productivity. Tim Johnson, a renowned expert in warehouse automation, once stated, "Selecting the right conveyor system is crucial for streamlining operations." This emphasizes the importance of making informed decisions.

When considering conveyor systems, it's essential to evaluate your specific needs. Various types exist, including belt, roller, and overhead conveyors. Each type serves different functions and is suited for different environments. A one-size-fits-all solution rarely exists. Think about your product size, weight, and flow requirements.

Moreover, understanding the potential setup challenges is vital. Space constraints can limit options. Sometimes, investments in specialized systems may seem daunting. However, the long-term gains often justify the initial costs. Reflect on your current processes and identify areas for improvement. Making the right choice requires careful thought and sometimes, a shake-up of old habits to embrace new technology.

Understanding Different Types of Conveyor Systems Available

When selecting a conveyor system, understanding the different types is crucial. Various conveyor systems are designed for specific needs. There are belt conveyors, roller conveyors, and overhead conveyors. Each type has its unique advantages and limitations. For instance, belt conveyors are great for moving bulk materials, while roller conveyors excel at transporting items with flat surfaces.

Tips: Consider the pace of your operations. If your workflow is fast, a high-speed conveyor might be necessary. Check the weight capacity needed for your products. Some conveyor systems can only handle light items, while others can carry heavy loads.

It’s essential to assess the layout of your facility. Some conveyor systems require more space than others. Overhead conveyors save ground space, but installation can be complex. Reflect on your specific environment. Not all systems adapt well. Choose what fits best, not just what looks good.

How to Choose the Right Conveyor Systems for Your Business?

| Conveyor Type | Best For | Load Capacity | Speed | Advantages |

|---|---|---|---|---|

| Roller Bed Conveyor | Heavy Items | Up to 500 lbs | Variable | Durable and flexible configuration |

| Belt Conveyor | Package Handling | Up to 2000 lbs | Up to 100 ft/min | Easy to use and maintain |

| Chain Conveyor | Heavy and bulky loads | Up to 10,000 lbs | Variable | Robust and efficient for extreme conditions |

| Gantry Conveyor | Heavy machinery | Up to 5,000 lbs | Slow to moderate | Ideal for assembly lines |

| Magnetic Conveyor | Metal Parts | Varies by size | Variable | Prevents slippage of parts |

Evaluating Your Business Needs and Requirements for Conveyor Systems

When considering conveyor systems, evaluate your business needs carefully. Start by analyzing the volume of products you handle daily. Understand how the system will improve efficiency and safety. A well-chosen conveyor can significantly reduce labor costs.

Tips: Think about the layout of your workspace. A compact design might be ideal for smaller facilities. Larger spaces may allow for complex systems, but remember, complexity can lead to more maintenance.

Next, consider the types of materials being transported. Different materials require different conveyor options. A system for heavy items differs from one for lightweight products. Additionally, reflect on the speed required for your operations. Too fast can lead to chaos, while too slow can hinder productivity.

Tips: Involve your team in the decision-making process. Their insights can reveal potential pitfalls. Also, consider future growth. Will your chosen system adapt as your business expands? Always plan for flexibility in your operations.

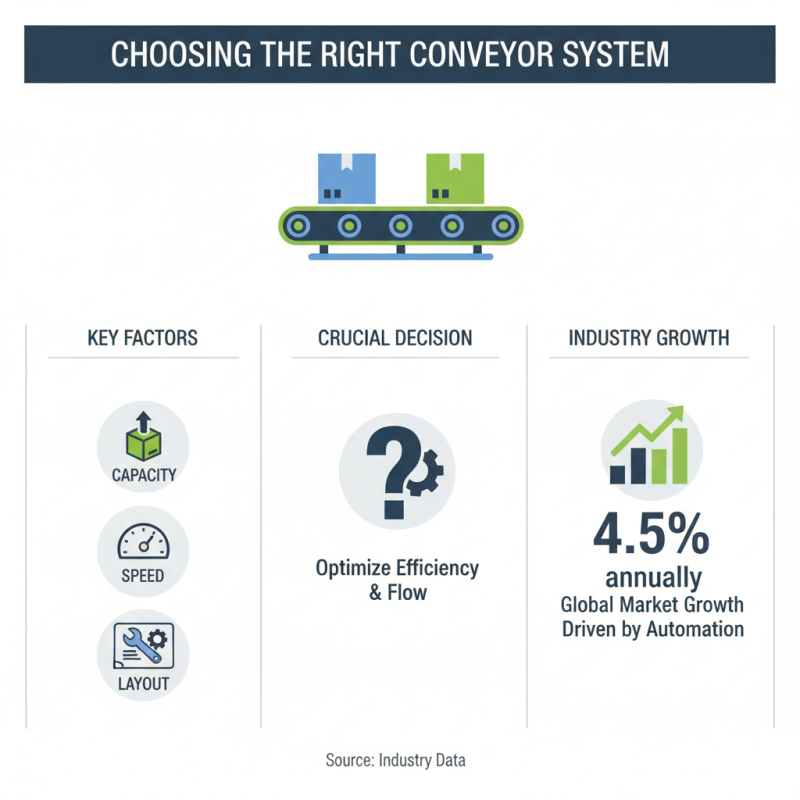

Key Factors to Consider: Capacity, Speed, and Layout

Choosing the right conveyor system for your business is a crucial decision. Capacity, speed, and layout are fundamental factors to consider. According to industry data, the global conveyor system market is expected to grow by 4.5% annually. This growth is driven by increasing automation needs across various sectors.

Capacity is key. Evaluate how many products you need to move per hour. Different systems can handle different loads. Research indicates that an optimal capacity can lead to a 20% increase in productivity. However, overestimating capacity can lead to system strain and maintenance issues. Accurate calculations are essential.

Speed is another critical factor. It directly impacts the efficiency of your operations. A speed mismatch can create bottlenecks. Reports show that the average conveyor speed ranges between 60 to 120 feet per minute. However, some businesses may need faster systems. Analyzing the layout is also vital. Space constraints can limit your choices. Poor layout choices may disrupt workflow. It is essential to balance speed and capacity with your workspace. Adjustments may be required as your business evolves. Understanding these factors will put you on the right path to selecting a suitable conveyor system.

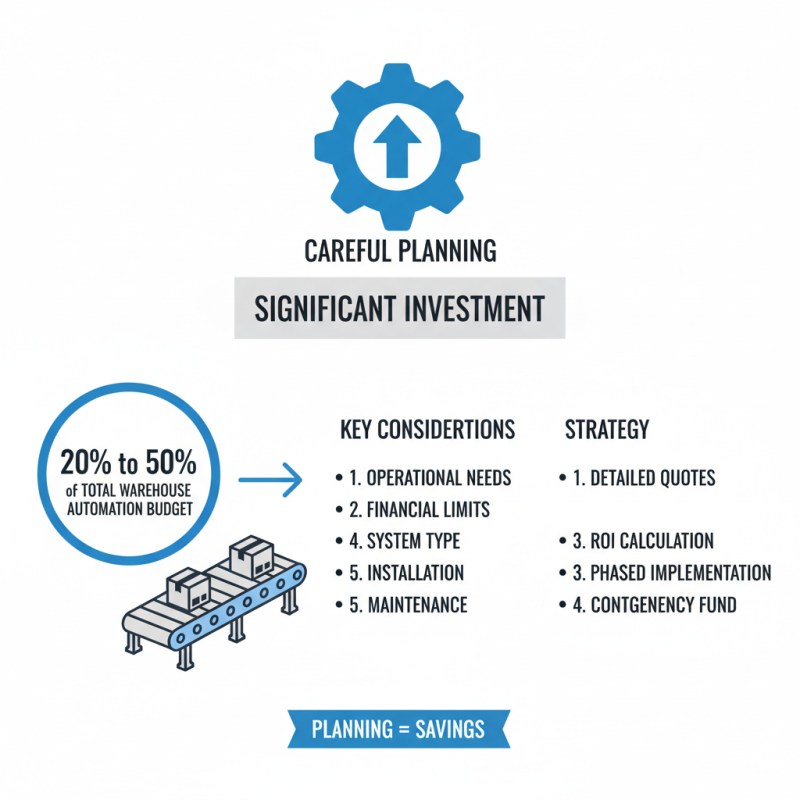

Assessing Costs and Budget Constraints for Conveyor Systems

Assessing costs and budget constraints for conveyor systems requires careful planning. According to a recent industry report, conveyor systems can represent 20% to 50% of the total budget for warehouse automation. This significant investment demands a clear understanding of your operational needs and financial limits.

Businesses often face challenges when estimating total costs. Factors such as installation, maintenance, and energy consumption play critical roles. For instance, maintaining a conveyor system may incur yearly costs of 5% to 10% of the initial purchase price. It’s crucial to factor in these ongoing expenses. Overly optimistic budget forecasts often lead to financial strain later.

Different industries have varying requirements. A packaging line might need a high-speed conveyor, while a retail operation may opt for a slower system with flexibility. Adjusting for these distinct needs can be tough. Miscalculating your needs can lead to wasted resources or inefficiencies. Understanding your budget thoroughly will help you make informed choices that align with your business goals.

Maintenance and Support: Ensuring Longevity and Efficiency

Maintaining a conveyor system is crucial for operational efficiency. Regular maintenance checks can prevent unexpected breakdowns. Small issues can escalate quickly if not addressed. Schedule routine inspections to identify wear and tear. Lubrication is key; neglecting it can lead to increased friction and energy costs.

Support is just as important. Establish a relationship with skilled technicians for emergency repairs. Sometimes, in-house staff may not have the expertise needed. It often leads to delayed responses and costly downtime. Training your team can bridge this gap but requires a commitment of time and resources.

You might face challenges in keeping track of regular maintenance. Documentation can be messy, and critical tasks may be overlooked. Adapt a simple tracking system to log maintenance activities. Regular audits of your maintenance plan will help improve it over time. Adjustments are necessary to meet evolving business demands.

Conveyor System Maintenance Costs and Frequency

This bar chart illustrates the average maintenance costs associated with different maintenance frequencies for conveyor systems. Regular maintenance is critical for ensuring longevity and efficiency in operations.

Related Posts

-

How to Choose the Right Conveyor Systems for Your Business Needs

-

Top 7 Conveyor Systems Innovations Driving Efficiency in Manufacturing in 2023

-

2025 Top 5 Conveyor Systems Innovations Transforming Industry Efficiency

-

Top 10 Benefits of Conveyor Systems in Modern Industries?

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

Inflatable Paint Booth Tips for Optimal Setup and Use?