OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

What is Powder Coating Equipment for Sale and How Does It Work?

Powder coating equipment for sale has gained significant traction in the manufacturing industry. Experts like John Smith, a leader in coating technology, emphasize, "Quality equipment is key to achieving durable finishes." This insight underlines the importance of choosing the right machinery for optimal results.

Understanding how this equipment works can make a difference. Powder coating involves applying a dry powder to a surface and curing it under heat. This process ensures a strong bond and uniform appearance. However, purchasing powder coating equipment requires careful consideration. Not all machines deliver reliable performance.

Many manufacturers face challenges in selecting the right tools. The options can be overwhelming and confusing. Potential buyers must evaluate their specific needs. It's essential to weigh factors like size, efficiency, and cost. As John Smith suggests, investing wisely in powder coating equipment for sale can elevate product quality. However, not every choice will be perfect. Take the time to research and reflect on what suits your operations best.

What is Powder Coating Equipment?

Powder coating equipment plays a critical role in the finishing industry. It refers to the machinery used to apply a dry powder to surfaces, providing a durable finish. Unlike traditional liquid paint, powder coating offers thicker layers without running or sagging. This technology is popular for metal surfaces in various sectors, including automotive and furniture manufacturing.

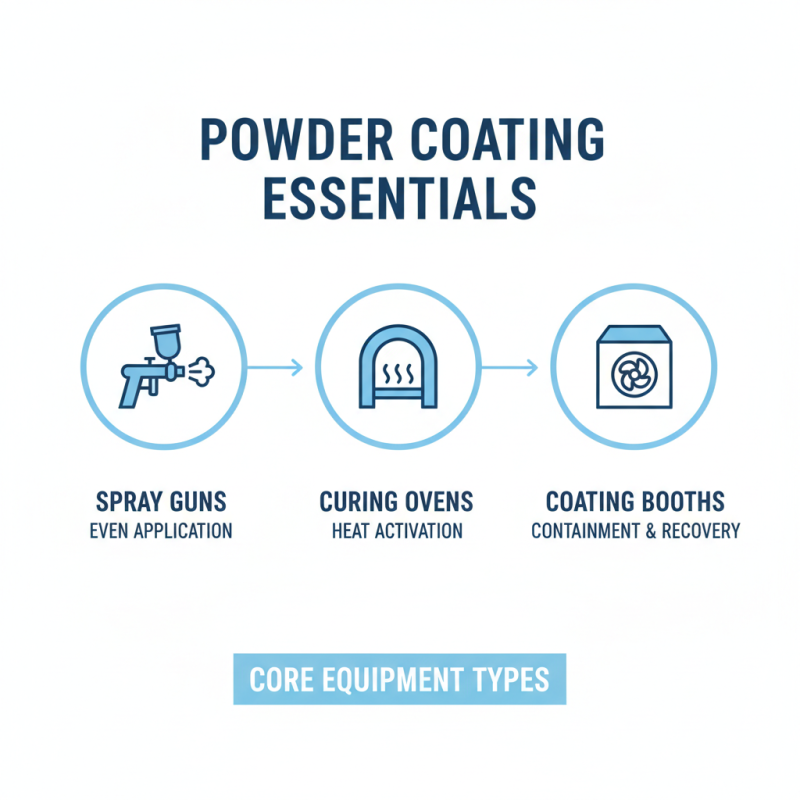

According to a recent industry report, the global powder coating market was valued at around $10.9 billion in 2021 and is expected to grow significantly. This growth stems from increasing demand for durable finishes in construction and automotive applications. The equipment typically includes a spray gun, a curing oven, and often a powder booth. These components work together seamlessly, ensuring an even coat and optimal curing conditions.

**Tip:** Always ensure proper ventilation when operating powder coating equipment. Safe air quality is vital for effective application and worker health. Additionally, regularly inspect your equipment for wear and tear. This can prevent costly downtime and improve your efficiency.

In this evolving sector, it’s vital to adapt and innovate. The challenge lies in finding the balance between quality and efficiency. Moreover, consider environmental impacts. Eco-friendly powder coatings are increasingly important for sustainable practices.

Types of Powder Coating Equipment Available for Sale

When exploring powder coating equipment, several types stand out in the market. The most common are spray guns, curing ovens, and booths. Spray guns are essential for applying powder evenly. They come in various models, allowing customization for different applications.

Curing ovens heat the coated items to create a strong bond between the substrate and powder. These ovens can vary in size and type, making them suitable for both small and large operations. Powder coating booths are critical for maintaining a clean environment. They help minimize contamination during the application process.

Tips: Always check the compatibility of equipment with your powder types. Using the wrong combination can lead to poor adhesion. Also, consider the size of your workspace. Too much equipment can crowd your area and reduce efficiency. Experimenting with settings may yield better results but requires patience. Each layer must be applied correctly. Learning from mistakes is part of the process.

How Powder Coating Equipment Operates: A Step-by-Step Guide

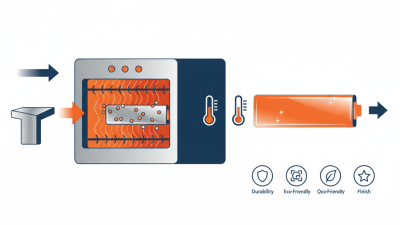

Powder coating is a popular finishing process that enhances durability and aesthetic appeal. It involves several steps that require specialized equipment. The process starts with surface preparation. This step is crucial and often overlooked. It typically includes cleaning and sometimes sandblasting to remove any impurities. According to industry studies, nearly 30% of coating failures are due to inadequate surface prep.

Next, the powder application takes place. Electrostatic spray guns are commonly used at this stage. The powder particles receive a positive charge, allowing them to cling to the grounded object. Precision in this step is necessary. Missed spots can lead to uneven finishes, which often reflects a lack of attention. Industry reports state that about 10% of products fail the quality inspection due to improper application.

After application, curing occurs in an oven. The heat melts the powder, creating a durable coating. This stage is where things can go wrong. Overheating can cause defects, weakening the bond. Some operators report that they struggle with maintaining consistent temperatures, leading to variations in product quality. It's an area for improvement, emphasizing the need for continual training in this evolving industry.

What is Powder Coating Equipment for Sale and How Does It Work? - How Powder Coating Equipment Operates: A Step-by-Step Guide

| Equipment Type | Functionality | Features | Typical Uses | Price Range (USD) |

|---|---|---|---|---|

| Powder Coating Gun | Sprays powder onto the surface | Electrostatic attraction, adjustable spray patterns | Metal, wood, and plastic items | $300 - $1,500 |

| Powder Coating Oven | Cures the powder coating | Temperature control, energy-efficient designs | Manufacturing and automotive applications | $5,000 - $20,000 |

| Powder Coating Booth | Contains overspray and recycles powder | Ventilation system, adjustable airflow | Industrial manufacturing, custom applications | $3,000 - $15,000 |

| Powder Recovery System | Recovers unused powder from the booth | High-efficiency filters, easy to clean | Enhancing material efficiency, reducing waste | $1,000 - $8,000 |

| Conveyor System | Moves items through the coating process | Automated operation, customizable layouts | Mass production lines, efficient workflow | $1,500 - $10,000 |

Key Features to Consider When Purchasing Powder Coating Equipment

When considering powder coating equipment for sale, there are essential features to evaluate. One crucial factor is the type of spray gun. Electrostatic guns provide better coverage and efficiency. Reports indicate that these guns can enhance transfer efficiency by up to 90%. That’s significant when reducing waste and optimizing costs.

Another important feature is the oven system. Uniform curing is vital for a durable finish. Most systems operate between 350°F to 450°F. Inadequate heating can lead to uneven coating. It's common for manufacturers to overlook this, risking quality. A consistent temperature can improve adhesion and longevity, which are critical factors for customer satisfaction.

Ventilation systems are also essential. Proper airflow prevents the buildup of hazardous fumes. Studies show that inadequate ventilation can double the risk of worker health issues. Facilities should prioritize safety features, including exhaust systems. This is often neglected in cost-cutting measures, yet it plays a crucial role in a productive workspace. Balancing cost and safety is always a challenge in the industry. Each of these elements contributes significantly to the overall performance and efficiency of powder coating operations.

Comparison of Different Types of Powder Coating Equipment

Maintenance Tips for Optimal Performance of Powder Coating Equipment

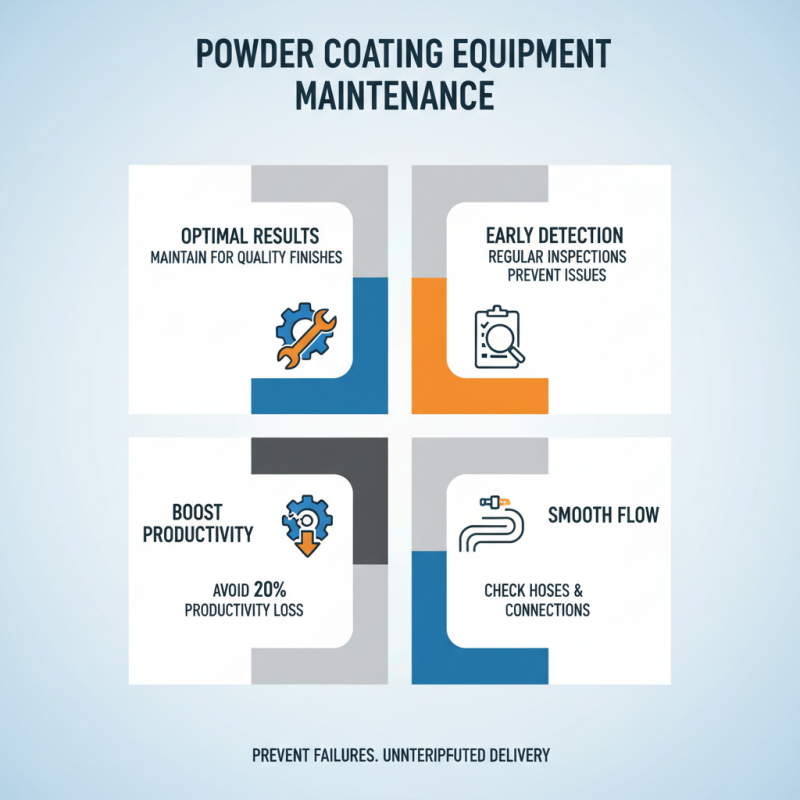

Maintaining powder coating equipment is vital for achieving the best results. Regular inspections can help catch potential issues early. According to industry reports, equipment failure can lead to a 20% loss in productivity. It's essential to check hoses and connections frequently. Faulty parts can disrupt the powder delivery process.

Cleaning is another critical aspect. The powder can accumulate and affect the quality of the coating. Some experts suggest a weekly cleaning routine to maintain equipment efficiency. Not all powders perform well under the same conditions. Factors like humidity and temperature can alter results. In fact, studies show that improper environmental control can reduce coating adhesion by up to 15%.

Operators should also pay attention to the curing process. The temperature uniformity in the oven is crucial. A temperature deviation of just 10 degrees can impact the finish quality. Regular calibration of thermocouples is necessary. Take time to assess how the equipment performs over time. Understanding the wear patterns can help in planning timely replacements.

Related Posts

-

Exploring the Future of Surface Finishing with Innovative Powder Coating Equipment for Sale

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

2025 Top 5 Powder Coating Equipment for Sale Options You Should Consider

-

10 Essential Tips for Choosing a Used Powder Coating Oven for Your Business

-

What is Powder Coating Oven and How Does It Work for Your Projects

-

How to Choose the Best Powder Coating Equipment in 2026?