OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

2025 Top Car Paint Booths for Professional Automotive Finishing

In the fast-evolving world of automotive finishing, selecting the right car paint booth is crucial for achieving impeccable results. As the industry continues to innovate, professionals are increasingly aware of the impact that a high-quality paint booth can have on both efficiency and finish quality. According to James Reynolds, a respected expert in the automotive paint industry, "The right car paint booth not only improves the quality of the finish but also enhances the productivity of the entire painting process." This statement underscores the importance of investing in top-tier equipment that meets the rigorous demands of professional automotive refinishing.

As we look ahead to 2025, the market is set to unveil a range of advanced car paint booths designed to optimize airflow, improve curing times, and ensure environmental safety. The latest trends are not just about maintaining high aesthetic standards; they are also closely tied to sustainability and compliance with new regulations. In this context, professionals must stay informed about the latest advancements in technology and design to remain competitive in the automotive painting sector. This article delves into the top car paint booths of 2025, offering insights into what makes each model stand out and how they can elevate your automotive finishing process.

Overview of Car Paint Booths in Automotive Industry

In the automotive industry, car paint booths play a crucial role in ensuring high-quality finishing. These specialized environments provide controlled conditions for the application of paint, which is essential for achieving the desired durability and aesthetic appeal of the vehicle. According to a report by the National Association of Automobile Manufacturers, over 85% of consumers prioritize paint quality when purchasing a vehicle, making the effectiveness of paint booths a critical factor for manufacturers.

The modern car paint booth must maintain precise temperature and humidity levels to optimize the curing process of paints and coatings. Research indicates that a well-regulated paint booth can reduce paint defects by up to 30%, leading to significant cost savings in rework and materials. Additionally, advancements in technology, such as the introduction of automated paint application systems, have increased efficiency while reducing waste. A recent industry study by the Automotive Paint Coating Association revealed that facilities utilizing advanced booths experienced a 25% increase in productivity, highlighting the importance of investing in high-quality paint booths for professionals in automotive finishing.

Key Features to Look for in a Professional Paint Booth

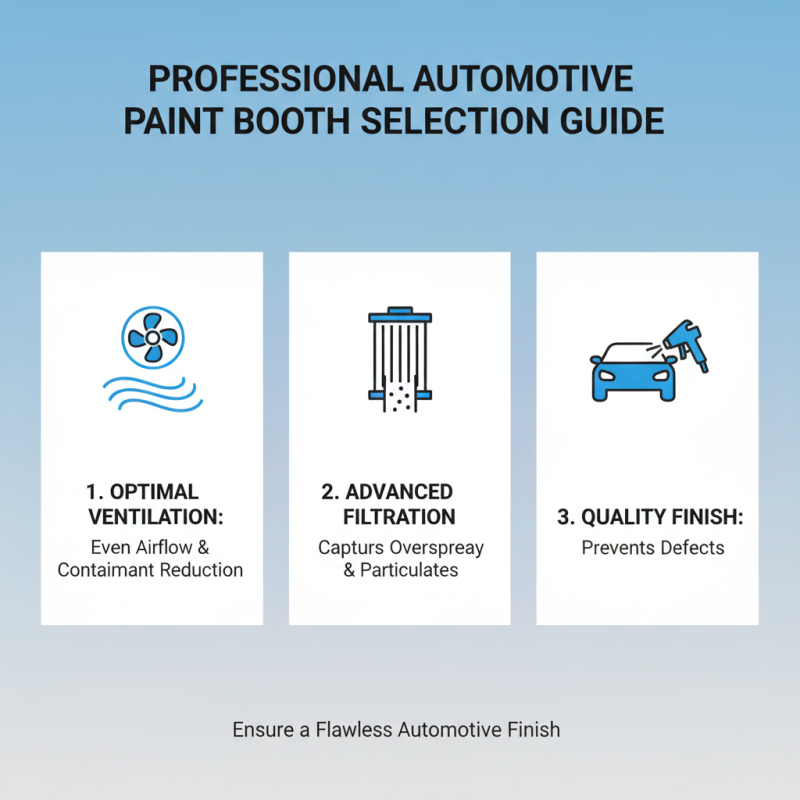

When selecting a paint booth for professional automotive finishing, it’s crucial to consider several key features that ensure both quality and efficiency in your work. First and foremost, a well-constructed paint booth should provide adequate ventilation. Proper airflow not only facilitates the even distribution of paint but also minimizes the risk of contamination from airborne particles. Look for booths that feature advanced filtration systems capable of capturing overspray and particulates, which can affect the final finish of the vehicle.

Another essential aspect is temperature and humidity control. The paint application process is sensitive to environmental factors, so a booth equipped with climate control systems helps maintain optimal conditions for curing and coating. An ideal paint booth should allow you to monitor and adjust these conditions easily, ensuring that the paint adheres properly and dries efficiently.

Tips: When assessing potential paint booths, pay close attention to ease of maintenance. A design that allows for easy cleaning and filter replacement will save you time and effort in the long run. Additionally, consider investing in a booth with a user-friendly control panel, which can streamline operations and improve productivity. By focusing on these critical features, you can choose a paint booth that enhances your professional automotive finishing capabilities.

Top Brands and Models for Car Paint Booths in 2025

As the automotive finishing industry continues to evolve, selecting the right car paint booth is crucial for achieving high-quality results. According to a recent industry report, the demand for advanced paint booths is projected to grow by 5% annually through 2025, driven by innovations in technology and an increased emphasis on sustainable practices. In particular, models featuring energy-efficient systems and enhanced airflow technologies are gaining popularity, allowing for faster drying times and improved paint finishes.

When choosing a paint booth, professionals should consider options that include automated controls, which can regulate temperature and humidity levels more precisely. This not only results in a superior finish but also minimizes the risk of defects caused by environmental changes. Reports indicate that booths with superior filtration systems can reduce harmful emissions by up to 90%, making them a more environmentally friendly choice.

**Tips:** Always prioritize booths that comply with the latest safety regulations and industry standards to ensure compliance and optimal performance. Additionally, maintain regular inspections and thorough cleaning of the booth to prolong its lifespan and guarantee consistent paint quality. Choosing a booth with modular designs can provide flexibility for future upgrades as technology advances in the automotive finishing sector.

2025 Top Car Paint Booths for Professional Automotive Finishing

| Model | Type | Size (ft) | Airflow (CFM) | Price ($) | Rating (out of 5) |

|---|---|---|---|---|---|

| Model A | Crossdraft | 20 x 10 | 1500 | 12,000 | 4.5 |

| Model B | Downdraft | 18 x 12 | 2000 | 15,000 | 4.8 |

| Model C | Semi-Downdraft | 22 x 12 | 1700 | 13,500 | 4.6 |

| Model D | Side Downdraft | 20 x 10 | 1600 | 11,000 | 4.3 |

| Model E | Portable | 10 x 8 | 800 | 4,000 | 4.0 |

Environmental Standards and Safety Regulations for Paint Booths

When it comes to automotive finishing, adhering to environmental standards and safety regulations in paint booths is paramount. These standards are designed to minimize air pollution, ensure worker safety, and promote sustainable practices. Paint booths must be equipped with proper ventilation systems that filter harmful fumes and particulates, preventing them from being released into the atmosphere. Additionally, employing water-based or low-VOC (volatile organic compound) paints can significantly reduce the environmental impact of automotive painting processes.

Tip: Regularly inspect and maintain your paint booth's filtration systems to ensure optimal performance. This will not only comply with regulations but also enhance the quality of your paint finishes.

Safety regulations also require that adequate personal protective equipment (PPE) be provided for workers, including respirators and protective clothing. Furthermore, implementing strict guidelines for handling and disposing of hazardous materials is crucial in maintaining a safe working environment.

Tip: Conduct regular training sessions for your staff on the importance of safety protocols and environmental standards. This education fosters a culture of compliance and reinforces the significance of these regulations in everyday operations.

By prioritizing environmental standards and workplace safety, automotive professionals can ensure top-quality finishes while safeguarding their workers and the planet.

Maintenance Tips for Optimal Performance of Paint Booths

Proper maintenance of paint booths is essential for achieving optimal performance in automotive finishing. According to a recent report by the Global Automotive Refinishing Market, regular upkeep of paint booths can enhance efficiency by up to 30%. This efficiency boost not only improves finishing quality but also reduces material waste. Key maintenance practices include regular cleaning of filters and booths, ensuring proper ventilation, and adhering to a strict schedule for equipment checks.

Neglecting these tasks can lead to a decline in air quality within the booth, which can adversely affect paint application and finish, leading to poor customer satisfaction and increased rework costs.

Furthermore, it's crucial to monitor the booth's temperature and humidity levels, as these factors play a significant role in paint curing. The American Paint Manufacturers Association emphasizes that maintaining optimal temperature ranges (between 70°F and 80°F) can decrease drying time and improve adhesion, yielding a superior finish on vehicles. Moreover, usage of quality paint materials and regular calibration of spray equipment contributes significantly to the longevity of paint booths. Regular maintenance not only affects the immediate output quality but also ensures that the equipment operates efficiently for an extended period, ultimately contributing to better operational savings and decreased downtime.

Related Posts

-

5 Essential Tips for Choosing the Perfect Small Paint Booth for Your Needs

-

The Ultimate Guide to Choosing the Perfect Small Paint Booth for Your Projects

-

Top 10 Spray Booth Filters You Need for Optimal Air Quality and Efficiency

-

Top 10 Used Paint Booths for Sale You Need to Check Out Today

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

The Ultimate Guide to Choosing the Best Mobile Paint Booth for Your Business Needs