OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

2025 Top Digital Spray Booth Filters for Enhanced Performance and Efficiency

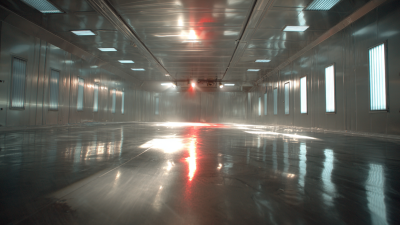

As the automotive and manufacturing industries continue to evolve, the demand for high-performance spray booth filters has become increasingly pivotal for operational efficiency and product quality. According to a recent report by MarketsandMarkets, the global spray booth market is projected to reach $2.4 billion by 2025, driven by advancements in technology and stricter environmental regulations. The implementation of top-quality spray booth filters not only enhances the finish quality of sprayed surfaces but also plays a crucial role in maintaining compliance with these regulations, ultimately reducing VOC emissions and improving indoor air quality.

The growth of the digital spray booth sector is particularly noteworthy, with a focus on ensuring that these critical components are optimized for efficiency. Industry studies indicate that advanced spray booth filters can improve particle capture rates by over 95%, significantly reducing the need for rework and boosting overall productivity. In 2025, selecting the right filter will be more important than ever, as manufacturers seek to balance cost-effectiveness with the need for enhanced filtration performance. This article will guide you through the top digital spray booth filters available, highlighting how they can enhance performance, increase efficiency, and safeguard both the environment and the end product.

Advancements in Filter Technology: Leading Trends in Digital Spray Booth Filters for 2025

In 2025, the landscape of digital spray booth filters is set to transform significantly due to groundbreaking advancements in filter technology. One of the leading trends is the integration of smart sensors within filters that monitor air quality and filter saturation in real-time. This innovation allows for proactive maintenance and replacement, ensuring optimal performance and reducing operational costs. Furthermore, the data collected can be analyzed to enhance user experience and improve overall efficiency in spray booth operations.

Another key development is the use of advanced materials like nanofibers, which provide higher filtration efficiency while maintaining low resistance to airflow. These materials not only capture smaller particles but also improve the longevity of the filters, thus lowering the frequency of replacements. Additionally, eco-friendly options are becoming more popular, as manufacturers strive to produce filters that are both efficient and sustainable. This shift not only meets regulatory standards but also appeals to environmentally conscious consumers, positioning digital spray booth filters at the forefront of the industry's push towards greener practices.

Performance Metrics: Key Data on Efficiency Gains with Modern Spray Booth Filters

In the fast-evolving world of spray booth technologies, modern filters play a pivotal role in promoting operational efficiency and minimizing waste. Recent performance metrics reveal significant efficiency gains attributable to advanced filtration solutions. These new filters not only enhance air quality but also contribute to reduced energy consumption, leading to substantial cost savings over time. Facilities employing cutting-edge digital spray booth filters have reported up to a 20% increase in application efficiency, underscoring the importance of integrating innovative technology into painting operations.

Tips for maximizing the effectiveness of your spray booth filters include regularly monitoring and replacing filters as needed to prevent clogs and maintain optimal airflow. Additionally, consider upgrading your filters to those with HEPA (High-Efficiency Particulate Air) capabilities to trap finer particulates, thus improving the overall quality of the paint application. Evaluating the performance metrics regularly can provide insights into potential areas for improvement, ensuring that your operations are always running at peak performance.

Cost-Benefit Analysis: Long-Term Savings from Upgrading to Top Digital Spray Booth Filters

Upgrading to top digital spray booth filters can lead to significant long-term savings for businesses in the coatings industry. While the initial investment might seem steep, the cost-benefit analysis makes a compelling case for this upgrade. Enhanced filter efficiency means reduced maintenance costs and fewer downtimes, allowing for uninterrupted production cycles. You’ll find that improved air quality not only protects your equipment but also enhances the overall working environment, leading to better employee productivity.

**Tips:** When considering an upgrade, evaluate the lifespan of the filters. High-quality digital filters may have longer operational timelines, ultimately reducing replacement frequency and costs. Additionally, compare energy consumption data; some of the latest models are designed to operate with lower energy inputs, providing savings on utility bills.

Investing in top digital spray booth filters is not just about adhering to regulatory standards but also about embracing a more efficient operational approach. By utilizing advanced filtration technology, businesses can reduce waste and enhance material utilization, translating to further financial benefits over time.

2025 Top Digital Spray Booth Filters for Enhanced Performance and Efficiency

| Filter Type | Average Cost ($) | Efficiency Rating (%) | Lifespan (Months) | Estimated Annual Savings ($) |

|---|---|---|---|---|

| High-Efficiency Filter | 150 | 95 | 12 | 300 |

| Standard Filter | 80 | 85 | 6 | 150 |

| Premium Digital Filter | 250 | 98 | 15 | 500 |

| Eco-Friendly Filter | 120 | 90 | 10 | 250 |

Environmental Impact: Reduction of VOCs and Waste with High-Performance Filter Systems

The reduction of volatile organic compounds (VOCs) is critical in today’s push for sustainable industrial practices. High-performance filter systems are at the forefront of this effort, effectively capturing harmful emissions and enhancing air quality. By integrating advanced filtration technologies, industries can significantly lower VOC emissions while improving overall operational efficiency. This is especially important in sectors such as automotive and manufacturing, where VOCs present a considerable environmental challenge.

Tips: Consider selecting filters made from sustainable materials that not only reduce emissions but also minimize waste. This can further enhance the sustainability of your operations. Regular maintenance and timely replacement of filters can also ensure that they perform at peak efficiency, thereby maximizing both effectiveness and lifespan.

Moreover, innovations like biomass-based and biochar filters illustrate a transition towards sustainable materials. These types of filters not only offer efficiency in air purification but also contribute to the reduction of landfill waste, transforming agricultural byproducts into valuable resources. Such efforts embody a holistic approach to reducing environmental impact while meeting regulatory standards.

2025 Top Digital Spray Booth Filters Performance Metrics

This chart displays the reduction of VOCs (Volatile Organic Compounds) emissions and waste generation by different filter systems in 2025. The data highlights the environmental benefits of using high-performance filters in digital spray booths.

User Feedback: Real-World Performance of the Top 10 Digital Spray Booth Filters in 2025

In 2025, user feedback on top digital spray booth filters has revealed significant insights into their real-world performance and efficiency. Among the top-rated filters, studies indicate that models with advanced HEPA filtration systems demonstrate enhanced particle capture rates, achieving over 99% efficiency in trapping airborne contaminants. This level of performance is crucial for maintaining the quality of finishes in various applications, including automotive refinishing and industrial coatings.

User reviews highlight how these filters not only extend the lifespan of spray booth equipment but also contribute to a cleaner working environment. Reports from industry experts suggest that the use of high-quality digital filters can lead to reduced material waste by improving overspray management and allowing for better paint adhesion. With increasing attention to environmental sustainability in the automotive and manufacturing sectors, these filters are seen as essential tools for both efficiency and compliance with stricter regulatory standards. As professionals continue to share their experiences, it becomes evident that investing in top-notch digital spray booth filters is pivotal for enhancing operational performance in 2025 and beyond.

Related Posts

-

The Ultimate Guide to Choosing the Perfect Small Paint Booth for Your Projects

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

Discover the Benefits of Inflatable Paint Booths for Your Next DIY Project!

-

Maximizing Efficiency: How a Car Paint Booth Transforms Auto Body Repair Processes

-

Essential Guide to Paint Booth Rental: Boost Your Business Efficiency with the Right Space

-

2025 Top 5 Conveyor Systems Innovations Transforming Industry Efficiency