OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

Top Powder Coating Equipment for Sale Essential Guide for Your Business?

In today's competitive manufacturing landscape, the need for high-quality finishing processes is crucial. Powder coating is increasingly popular due to its durability and environmental benefits. According to industry reports, the global powder coating market is expected to reach $27 billion by 2025, highlighting its significance. Business owners seeking "powder coating equipment for sale" must consider various factors for optimal investment.

High-performance equipment enhances efficiency and product quality. However, it can be overwhelming to choose the right tools. Understanding equipment specifications, maintenance requirements, and the latest technology trends is vital. A comprehensive knowledge of these elements can maximize returns. Yet, even the best equipment may struggle without skilled operators and a proper workflow in place.

Investing in powder coating equipment requires careful evaluation. While the allure of advanced machinery is compelling, businesses must reflect on their specific needs. This reflection helps prevent overspending on features that may not provide real value. Ultimately, choosing the right powder coating equipment can significantly elevate a company's production capabilities.

Overview of Powder Coating Equipment Types and Uses

When considering powder coating equipment, it's crucial to understand the various types available. There are several key categories. Each type has unique features and applications. For example, spray booths are vital for ensuring an even coat. They minimize overspray and protect the environment. Ovens are essential for curing the powder effectively, ensuring durability.

Another important type is the powder coating guns. These guns come in manual and automatic versions. The right gun choice impacts coating quality significantly. Investing in a high-quality gun can enhance productivity. Some operators may rush this choice, leading to inconsistencies. Remember, attention to detail is vital.

Tip: Always test different powders to see which works best for your equipment. A specific powder may not yield the desired finish, so experimentation is key.

Another noteworthy type is the reclaim system. This system collects unused powder, reducing waste. Many businesses overlook this feature. It can save costs over time. However, proper maintenance is required to maximize effectiveness.

Tip: Review your reclaim process regularly. A clogged system can lead to lost material and increased expenses. This oversight can affect overall efficiency, so stay vigilant.

Key Features to Consider When Choosing Powder Coating Equipment

Choosing the right powder coating equipment is crucial for your business. Start by considering the size of your operation. Smaller workshops may need compact systems. Larger facilities often require more extensive setups. The layout of your space also matters. Ensure the equipment fits comfortably without hindering workflow.

Another key feature is the heating system. Proper curing is essential for durability. Look for systems that maintain consistent temperatures. Also, consider the type of powder used. Different powders may require specific equipment settings. Investing in adjustable systems can enhance versatility.

Don’t overlook the ease of maintenance. Some machines are complex and may lead to downtime. Seek user-friendly equipment with accessible parts. Training your staff is important as well. Intuitive controls can minimize errors. Reflect on these aspects before making a decision. The right choice will support your business growth effectively.

Top Powder Coating Equipment Performance Comparison

Top Powder Coating Machines and Their Specifications

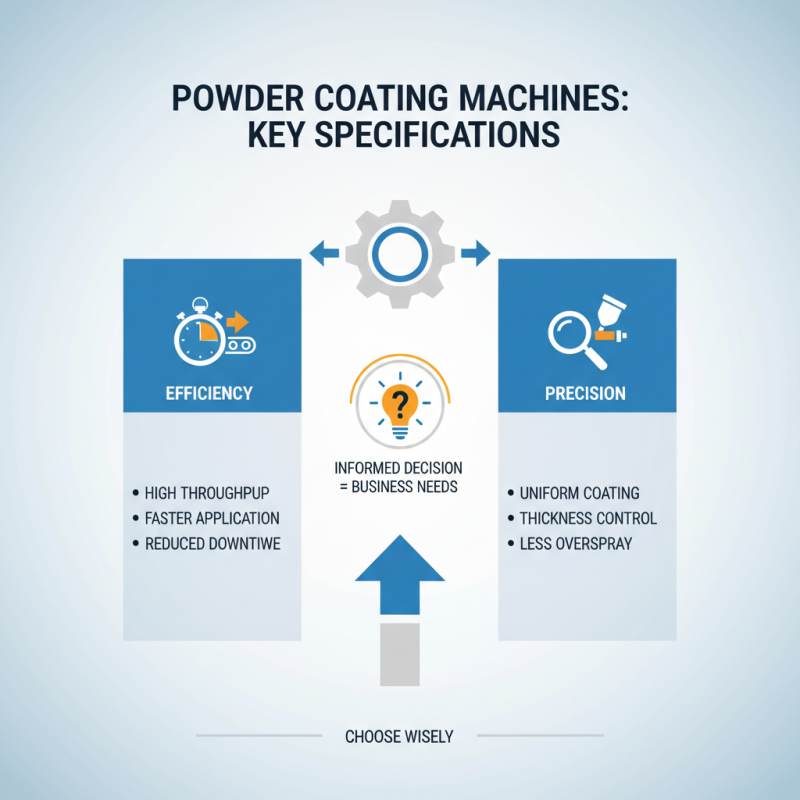

When exploring powder coating machines, specifications are crucial. Different machines offer various features to meet diverse business needs. Some machines focus on efficiency, while others prioritize precision. Understanding these factors can help you make an informed decision.

For instance, consider the size of the machine. Compact versions are suitable for small spaces but may limit output. Larger models increase productivity, yet they require more room and energy. Pay attention to the temperature range. A wider range allows for flexibility in different materials and coatings.

Moreover, design matters. An intuitive interface can save time and reduce the learning curve for new operators. Always check the warranty and customer support options as well. A warranty eases concerns about maintenance, while good support ensures your operations run smoothly. Reflect on your business’s specific needs before making a purchase.

Best Practices for Maintaining Powder Coating Equipment

Maintaining powder coating equipment is crucial for efficiency. Regular cleaning is essential. Dust and debris can hinder performance. Make it a routine, checking filters frequently. A clean machine produces consistent results.

Inspecting components is equally important. Look for wear and tear. Nozzles may clog, reducing spray patterns. Replace worn parts promptly to avoid larger issues. This attention to detail can save time and money later. Keeping a maintenance log helps track these changes.

Operator training cannot be overlooked. Ensure all team members understand equipment use. A small mistake can cause significant setbacks. Encourage questions and discussions about best practices. Involve your team in the maintenance plan, creating a sense of ownership. This can lead to better care of the equipment.

Top Powder Coating Equipment for Sale Essential Guide for Your Business - Best Practices for Maintaining Powder Coating Equipment

| Equipment Type | Key Features | Maintenance Frequency | Average Cost |

|---|---|---|---|

| Powder Coating Gun | Electrostatic charging, adjustable output | Monthly | $2,000 - $5,000 |

| Powder Coating Oven | Temperature precision, energy efficient | Quarterly | $8,000 - $25,000 |

| Powder Recovery System | High efficiency, easy to clean | Monthly | $1,500 - $4,000 |

| Conveyor System | Automated movement, adjustable speed | Every 6 months | $5,000 - $15,000 |

| Washing System | High-pressure cleaning, eco-friendly | Monthly | $3,000 - $10,000 |

Cost Analysis: Budgeting for Powder Coating Equipment Investments

Investing in powder coating equipment requires careful budgeting. Start by considering the initial costs. Basic units can range from a few thousand to tens of thousands of dollars. Installation and training add more expenses. Don’t forget ongoing costs like maintenance, filters, and powders. These can significantly impact your budget.

It’s also essential to evaluate the return on investment. Will this equipment increase production efficiency? Consider the time saved. Faster processes can lead to higher profits. However, assess your business needs carefully. Overspending on machinery that isn't necessary can hurt your finances.

Think about your production volume. If you’re a small business, investing in heavy-duty equipment might not be wise. Sometimes, starting small and scaling up feels prudent. Always leave room for unexpected costs. Each piece of equipment often has hidden expenses. Being aware can save you from financial strain later on.

Related Posts

-

2026 Top Powder Coating Booth for Sale Options to Consider?

-

Understanding the Benefits of Powder Coating Equipment for Your Business Growth

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

What is Powder Coating Equipment for Sale and How Does It Work?

-

Top Powder Coating Equipment Package Options for Your Needs?

-

Exploring the Future of Surface Finishing with Innovative Powder Coating Equipment for Sale