OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

Top Powder Coating Equipment Package Options for Your Needs?

In the world of industrial finishing, selecting the right powder coating equipment package is critical. According to industry expert John Smith, "Choosing the right package can significantly improve efficiency and output." A well-suited powder coating equipment package not only enhances productivity but can also streamline workflows.

Many businesses struggle with the decision-making process. Factors like size, capacity, and features create confusion. It's essential to assess specific needs to find the perfect fit. Some packages may look appealing but fail under real-world conditions. Investigating user reviews and seeking expert advice can provide valuable insights.

A tailored powder coating equipment package should adapt to unique requirements. Think about aspects such as the types of materials you coat and your production volume. The right choice can elevate your operations. However, the industry is evolving quickly, and staying informed can be challenging. Regular reflections on equipment performance ensure continuous improvement. Embracing this journey leads to better outcomes in the long run.

Understanding Powder Coating Equipment Packages

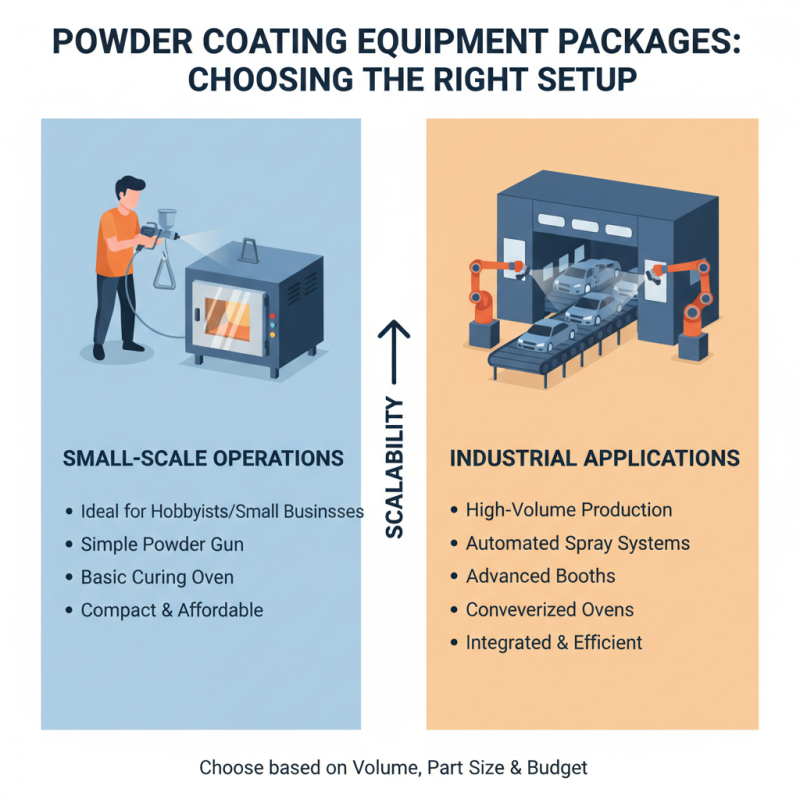

When it comes to powder coating, choosing the right equipment package is essential. Equipment packages come in various configurations to suit different needs. Some packages focus on small-scale operations, while others are designed for larger industrial applications. A small package may include a simple gun and a basic curing oven, ideal for hobbyists. In contrast, a larger setup could incorporate advanced booths and automated systems.

Understanding your specific requirements will greatly influence your decision. Consider the types of materials you will coat and the production volume. While some packages offer versatility, they may not always maximize efficiency. A compact setup can save space but might limit the output. Conversely, a more comprehensive package could provide what you need but might feel overwhelming at first.

Remember, inefficiencies can arise. A machine might not function as expected, or components may require frequent adjustments. Finding the right balance is crucial. Assessing your skills and the level of support available is part of the process. Sometimes, simpler options can lead to unexpected benefits. Be reflective about your choices, and don't shy away from seeking feedback or making changes.

Key Components of Powder Coating Systems

When exploring powder coating systems, key components play a crucial role in performance and reliability. A powder coating system typically includes several main parts: a spray gun, a curing oven, and an air compressor. The spray gun atomizes the powder and applies it evenly. Choosing the right spray gun ensures optimal coverage and finish.

The curing oven is where the magic happens. It heats the coated items to a specific temperature, allowing the powder to melt and form a durable layer. Proper temperature control is vital. If temperatures are inconsistent, it can lead to uneven curing. Users often overlook this aspect.

Tips: Always test your oven's temperature calibration. A discrepancy of just a few degrees can impact the final product. Additionally, regularly maintain your air compressor to avoid moisture buildup. This simple step can prevent defects in the coating process.

Remember that each component must work in harmony. If one part fails, the entire operation can suffer. Pay attention to your system's specific needs. Adjustments may be necessary based on the materials you are coating. Experimenting with different settings can lead to improved quality, but be cautious. It takes time and patience to achieve the best results.

Top Powder Coating Equipment Package Options

This chart presents the average costs of various key components used in powder coating systems. The data illustrates the financial investment typically required for each component, highlighting the importance of selecting the right package for your needs.

Factors to Consider When Choosing Equipment

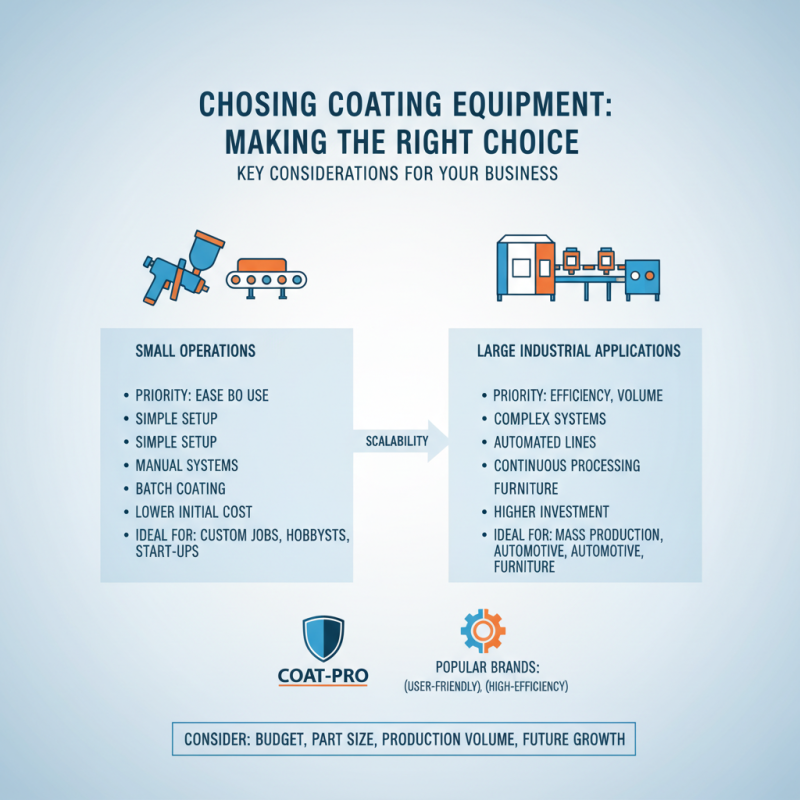

Choosing the right powder coating equipment involves several key factors. Consider the size and scope of your operations. A small workshop may not need the same capacity as a large industrial setup. Evaluate the productivity you require. High demand may necessitate advanced features and automation.

Tips: Think about the available space. Equipment should fit comfortably in your workspace. Avoid overcrowding, as it can lead to inefficiencies.

Another important aspect is the type of materials you’ll be working with. Some equipment performs better with certain materials. Do your research to match your equipment with your specific needs.

Tips: Check for versatility. Can the equipment handle different types of powders? This flexibility can save you from having to invest in additional machines.

Finally, don't overlook the after-sales support. Maintenance and service can affect your equipment's longevity. Poor support can lead to unexpected downtime.

Tips: Ensure you have access to help when needed. An underwhelming service can lead to frustration and loss of productivity. Keep these factors in mind as you explore your options.

Comparing Popular Powder Coating Equipment Brands

When selecting powder coating equipment, understanding the options available is crucial. Various brands offer a range of systems, each with unique features. Some may prioritize user-friendliness, while others focus on efficiency. It's essential to consider what your specific needs are. A straightforward setup may benefit small operations. More complex systems might suit larger, industrial applications.

Many brands provide equipment with different curing technologies. Infrared and convection heating options are popular. However, the right choice often depends on the materials you are working with. Sometimes, users find that their selected equipment doesn't meet all their production requirements. It’s a reminder to evaluate your existing processes and identify potential gaps in efficiency.

Customer support and warranty options vary significantly between manufacturers. Understanding these aspects can impact long-term satisfaction with your investment. Engaging with peers about their experiences can provide insightful perspectives. Taking the time to research and reflect on these elements can lead to a more informed decision.

Maintaining and Troubleshooting Your Powder Coating Setup

Maintaining a powder coating setup can be challenging. Regular inspection is crucial. Check for clogged filters and ensure proper airflow. A small clog can create uneven surfaces, leading to frustrating results. Be proactive and clear any blockages before they become bigger issues.

Troubleshooting is part of the process. If you notice poor adhesion, examine your prep work. Contaminants on the surface can lead to failure. It’s also important to adjust the curing temperature. Too low or too high can ruin the finish.

Don’t hesitate to experiment. Keep a log of what works and what doesn’t. Every setup is unique. Learning from mistakes will improve your efficiency. Analyze the results and adjust accordingly for better outcomes.

Related Posts

-

Unleashing Efficiency: The Ultimate Guide to Choosing Powder Coating Equipment for Sale in 2023

-

Exploring the Future of Surface Finishing with Innovative Powder Coating Equipment for Sale

-

Top Powder Coating Equipment Trends to Watch in 2025

-

Top 10 Small Powder Coating Ovens for Efficient Home Use

-

What is Powder Coating Equipment for Sale and How Does It Work?

-

2026 Top Powder Coating Booth for Sale Options to Consider?