OPEN FROM 9AM TO 5PM – CLOSED ON WEEKENDS

Transform Your Painting Process: The Ultimate Guide to Choosing an Ideal Paint Booth for Maximum Efficiency

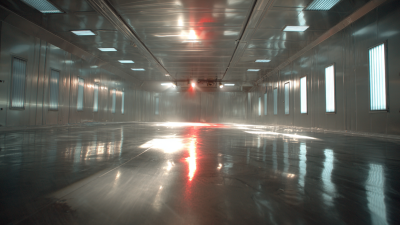

In the world of painting, whether in an industrial or creative setting, choosing the right equipment significantly impacts the quality and efficiency of the work produced. One of the most crucial pieces of equipment in this process is the ideal paint booth. An ideal paint booth is not just a space to apply paint; it serves as an environment that maximizes productivity while ensuring safety and quality control. This ultimate guide aims to transform your painting process by exploring the essential features to consider when selecting a paint booth, providing tips on optimizing workflows, and discussing how the right booth can enhance the overall outcome of your projects. Understanding how to choose the ideal paint booth can lead to improved finishes, reduced waste, and heightened efficiency, making it a vital aspect of any painting operation.

Understanding the Importance of Paint Booth Efficiency in Industrial Applications

In industrial applications, the efficiency of a paint booth plays a crucial role in determining the overall productivity and quality of the finishing process. A well-designed paint booth not only minimizes overspray and waste but also enhances air circulation and contamination control. This results in a smoother finish and reduces the likelihood of defects that require rework, ultimately saving both time and resources.

**Tip 1:** When choosing a paint booth, consider its airflow system. A balanced airflow prevents dust and debris from settling on freshly painted surfaces, ensuring a superior finish every time.

Furthermore, the type of materials and equipment used in the booth can significantly impact efficiency. Selecting appropriate filtration systems can also aid in maintaining air quality, prolonging the lifespan of equipment, and reducing the frequency of maintenance. An effective paint booth should accommodate the specific needs of your projects while optimizing the workflow.

**Tip 2:** Regularly assess the layout of your booth. Efficient space utilization and easy access to tools and materials can streamline processes and reduce downtime, allowing for a more effective painting operation.

Efficiency of Different Paint Booth Types

Key Factors Influencing Paint Booth Selection for Enhanced Productivity

When selecting a paint booth, several key factors can significantly enhance productivity during the painting process. First and foremost, the size and design of the booth must accommodate the scale of your projects. A well-sized booth allows for easier maneuvering of equipment and materials, reducing time spent on adjusting or repositioning items. Additionally, considering the airflow system is crucial; optimal airflow minimizes dust contamination and ensures even paint application, leading to high-quality finishes and reduced rework time.

Another important factor is the type of filters used in the booth. High-efficiency filters enhance air quality and provide a cleaner working environment, which not only boosts worker satisfaction but also contributes to better paint adhesion and drying times. Moreover, the energy efficiency of the booth should not be overlooked. Investing in a booth with energy-efficient features can lower operational costs and improve overall productivity by allowing workers to focus on their tasks rather than managing excess energy expenditures. By carefully considering these elements, businesses can significantly transform their painting processes.

Analyzing the Impact of Paint Booth Size on Workflow and Space Optimization

When selecting a paint booth, one of the most critical factors to consider is its size, as it plays a pivotal role in optimizing workflow and maximizing space efficiency. According to a study by the National Association of Manufacturers, approximately 52% of manufacturers reported that inadequate space significantly hampered their production processes. A well-sized paint booth allows for seamless movement of materials and personnel, reducing bottlenecks and enhancing overall productivity. Ideally, a larger booth accommodates various project sizes, enabling operators to work on multiple components simultaneously without the risk of cross-contamination or damage.

Moreover, the impact of proper space utilization cannot be overstated. The Occupational Safety and Health Administration (OSHA) emphasizes that an organized workspace not only boosts productivity but also enhances worker safety. A spacious and well-structured paint booth minimizes the likelihood of accidents, as employees can maneuver freely and access tools without obstacles. An investment in an appropriately sized booth, therefore, translates into substantial long-term benefits, driving both efficiency and safety in the painting process. By understanding these dynamics, businesses can make informed choices that align their operational needs with effective space management.

Transform Your Painting Process: The Ultimate Guide to Choosing an Ideal Paint Booth for Maximum Efficiency

| Paint Booth Size (ft) | Workflow Efficiency (%) | Space Utilization (%) | Recommended Projects |

|---|---|---|---|

| 10 x 10 | 65 | 70 | Small furniture, craft projects |

| 12 x 20 | 75 | 80 | Medium-sized furniture, automotive parts |

| 16 x 30 | 85 | 85 | Large furniture, industrial equipment |

| 20 x 40 | 90 | 90 | Custom projects, large-scale manufacturing |

The Role of Airflow and Filtration Systems in Achieving Quality Finishes

Airflow and filtration systems are crucial components of an efficient paint booth, significantly impacting the quality of the finishes achieved in automotive, industrial, and furniture painting processes. According to a report by the National Institute for Occupational Safety and Health (NIOSH), effective ventilation can reduce airborne contaminants by up to 90%. This reduction not only improves the quality of the paint finish but also enhances worker safety by limiting exposure to hazardous fumes.

The design of airflow systems should ensure that fresh air is continuously introduced while simultaneously removing overspray and hazardous particles from the booth. A balanced airflow system not only maintains optimal working conditions but also aids in achieving uniform paint application.

The Association of Equipment Manufacturers (AEM) states that proper filtration can capture particles as small as 0.5 microns, which is essential for preventing blemishes and imperfections on painted surfaces. By investing in high-quality filtration and airflow systems, businesses can achieve higher efficiency and superior finish quality, ultimately leading to greater customer satisfaction and reduced rework.

Cost-Benefit Analysis: Investing in Advanced Paint Booth Technologies for Long-term Gains

Investing in advanced paint booth technologies can significantly enhance operational efficiency and profitability for businesses in the painting industry. According to a report by the National Association of Manufacturers, over 25% of manufacturing costs can be attributed to inefficient processes. By implementing a modern paint booth, companies can reduce overspray and contamination, which leads to higher-quality finishes and material savings. A study from the American Coatings Association suggests that using high-efficiency paint booths can reduce paint waste by up to 30%, translating directly to cost savings.

Moreover, advanced paint booths are designed to meet stringent environmental standards, which can mitigate the risk of regulatory fines. Research indicates that companies adopting greener technologies, including state-of-the-art paint booths, can enhance their brand reputation and attract eco-conscious clients. According to a report from IBISWorld, industries that prioritize sustainability see, on average, a 15% growth in customer loyalty and sales. Therefore, the initial investment in advanced paint booth technology not only pays off through increased efficiency and reduced waste but also positions a company favorably in a competitive market focused on sustainability and quality.

Related Posts

-

Understanding the Benefits of Powder Coating Equipment for Your Business Growth

-

Maximizing Efficiency: How a Car Paint Booth Transforms Auto Body Repair Processes

-

The Ultimate Guide to Choosing the Perfect Small Paint Booth for Your Projects

-

Discover the Benefits of Inflatable Paint Booths for Your Next DIY Project!

-

Essential Guide to Paint Booth Rental: Boost Your Business Efficiency with the Right Space